How To Set Pinion Angle On Lowered Truck? Easy Guide

This article will explain How To Set Pinion Angle On Lowered Truck? Setting the pinion angle on a lowered truck is crucial for ensuring optimal performance and reducing driveline vibrations. In the first few lines, we’ll delve into why it’s important, what tools you’ll need, and how to get it done right. This guide aims to provide a comprehensive look at how to set the pinion angle on your lowered truck.

Key Takeaways

- Importance of setting the correct pinion angle

- Tools required for the job

- Steps to measure and adjust the pinion angle

- Common mistakes to avoid

How To Set Pinion Angle On Lowered Truck?

Setting the pinion angle on a lowered truck is a critical task that ensures the proper alignment of the driveline, thereby reducing vibrations and enhancing performance. The process involves several steps, including measuring the existing angle, making adjustments, and verifying the new settings. Here’s a detailed guide on how to go about it:

Measuring the Existing Angle

- Park your truck on a level surface.

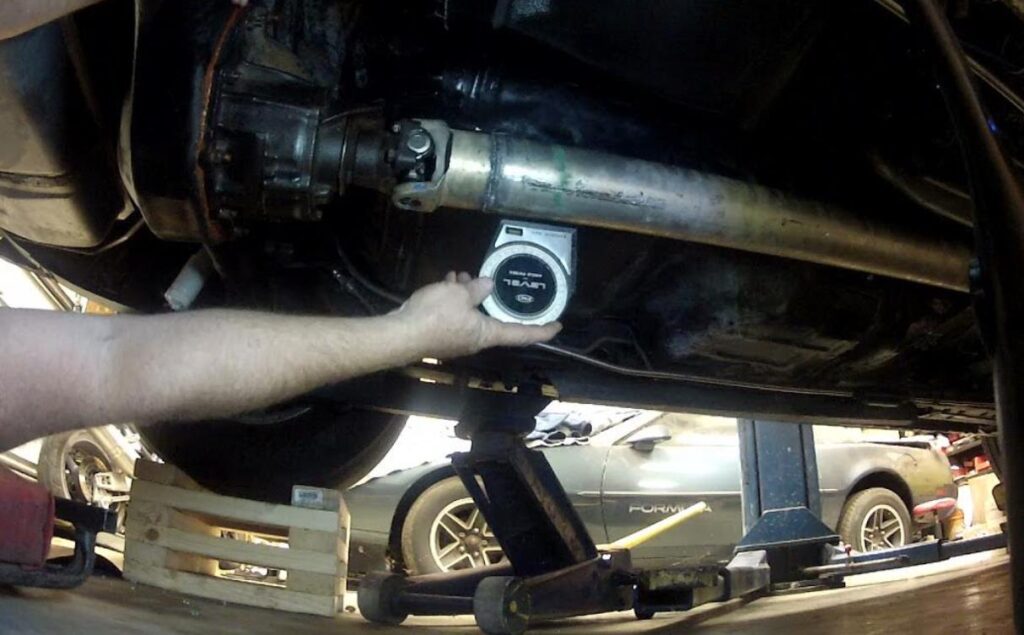

- Use a digital angle finder to measure the existing pinion angle. Place the angle finder on the face of the balancer on the front of the motor and record the angle.

Making Adjustments

- If the angle is not within the recommended range, you’ll need to adjust it.

- Use shims or spacers to make the necessary adjustments. For example, Belltech shims can correct the pinion angle by rotating the rear differential back into alignment.

Verifying the New Settings

- Once you’ve made the adjustments, use the digital angle finder again to measure the new pinion angle.

- Double-check to ensure it’s within the recommended range.

Importance of Correct Pinion Angle

The pinion angle plays a significant role in the drivability and performance of your truck. An incorrect angle can lead to issues such as vibrations, premature wear of components, and even driveline failure.

Why It Matters?

- Reduced Vibrations: A correct pinion angle minimizes driveline vibrations.

- Longevity: It extends the life of U-joints and other driveline components.

- Performance: Optimal pinion angle improves torque and power transfer.

Tools Required

Before you start, gather the following tools:

- Angle Finder

- Wrench set

- Jack and Jack stands

- Chalk or marker

Optional Tools

- Digital Protractor

- Torque wrench

Measuring the Pinion Angle

To measure the pinion angle, follow these steps:

- Lift the Truck: Use a jack to lift the rear end of the truck.

- Secure the Truck: Place jack stands under the truck for safety.

- Locate the Pinion: Find the pinion yoke on the rear axle.

- Measure the Angle: Use an angle finder to measure the angle.

Tips for Accurate Measurement

- Ensure the truck is on a level surface.

- Double-check your measurements.

Adjusting the Pinion Angle

After measuring, you may need to adjust the pinion angle. Here’s how:

- Loosen the U-bolts: Use a wrench to loosen the U-bolts connecting the leaf springs.

- Adjust the Shims: Insert or remove shims to adjust the angle.

- Tighten the U-bolts: Secure the U-bolts back in place.

- Re-measure: Use the angle finder to confirm the new angle.

Common Mistakes to Avoid

- Over-tightening the U-bolts

- Not double-checking the measurements

Advanced Techniques for Setting Pinion Angle on Lowered Trucks

Calculating the Pinion Angle with Precision

Accurate calculation of the pinion angle is crucial for the safety and performance of your lowered truck. Using a protractor or a digital meter, you can measure the existing angle and adjust it accordingly.

The arc tan formula can be useful for this calculation, especially when you have the dimensions of the driveshaft and the size of the rear axle.

Formula for Calculation

The formula involves dividing the length of the driveshaft by the size of the rear axle and applying the arc tan formula for precise measurement.

Using Shim Kits for Alignment

Shim kits offer a quick and efficient way to align the pinion angle. These kits come with steel-based components designed to fit between the back ends of the truck. They also include leaf springs that help in aligning the angle at the correct position.

Installation Steps

- Lift the truck using a hydraulic jack.

- Unbolt the driveshaft from the frame.

- Install the shims in the rear end.

- Reassemble the driveshaft and lower the truck.

Importance of Spacers

Spacers can be a valuable addition to your truck for adjusting the pinion angle. They not only facilitate more ground clearance but also help in reducing vibrations in the driveline.

How to Install Spacers?

- Mount them between the truck’s chassis and transmission system.

- Check the length of the tail shaft.

- Adjust a 3.8-inch nut and drill the threads.

- Install the spacer in the suspension system.

Re-tightening the Housing

The last step in setting the pinion angle involves re-tightening the housing. This ensures that the adjustments made are stable and long-lasting.

Steps for Re-tightening

- Measure the raised value of the springs.

- Examine the U-bolts that hold the pinion with the driveshaft.

- Adjust the torque of the built-in bolts according to calculated values.

How To Get The Right Pinion Angle?

Getting the right pinion angle is crucial for the performance and longevity of your lowered truck. To achieve this, you can follow a series of steps that involve measuring and adjusting the angle.

One of the techniques includes using a digital angle finder to measure the angle on the face of the balancer on the front of the motor.

After recording the number, you can proceed to adjust the angle using shims or spacers. For coil-sprung muscle cars, you can also use specialized tools and apps like the Spicer website and Tremec App to calculate the pinion angle accurately.

What Should Pinion Angle Be Set At?

The ideal pinion angle varies depending on the type of truck and its suspension system. For lowered trucks with leaf spring suspensions, the angle is usually set at 6 or 7 degrees. This helps in reducing driveline vibrations and ensures a smooth ride.

For trucks with a 4-link suspension system, the angle can be adjusted at ride height for more precise settings. It’s essential to consult the manufacturer’s guidelines or seek professional advice to determine the ideal angle for your specific truck model.

Does A Car Need To Be Level To Set Pinion Angle?

Yes, it’s crucial for the car to be level when setting the pinion angle. This ensures that the measurements are accurate and that the driveline components align correctly.

The vehicle should be set up at its intended ride height and leveled side to side before beginning the process.

A bubble level can be used to ensure that the frame is perfectly level. Once the vehicle is leveled, you can proceed with measuring and adjusting the pinion angle. It’s also important to consider the front-to-rear rake of the vehicle when setting it up.

What Is The Correct Pinion Angle For A 2 Piece Driveshaft?

The correct pinion angle for a 2-piece driveshaft is a bit more complex to set than a single-piece driveshaft. The key is to ensure that both sections of the driveshaft are aligned correctly. The pinion on the rear end should be set at the same angle as the trans tail shaft.

For instance, if the trans tail shaft is 3 degrees downward, the pinion will point 3 degrees upward. However, the driveshaft should not be perfectly straight from the trans to the rear end, as the U-joints will run dry and fail. Some angle is advisable in the U-joints, but ensure the pinion and trans tail shaft are at equal angles.

Conclusion

In summary, understanding how to set the pinion angle on a lowered truck is essential for optimal performance and longevity of your vehicle. By following this guide, you can ensure a smoother ride and extend the life of your driveline components.

Top FAQ’s

Should the rear end pinion angle be up or down?

The rear-end pinion angle is best positioned where it is pointing upward. This elevation helps in reducing driveline vibrations and ensures better performance.

What is the ideal pinion angle for a very low truck?

For trucks that sit very low, the ideal rear-end pinion angle on leaf spring cars is usually set at 6 or 7 degrees. This helps in maintaining a balance between performance and safety.

Can you adjust the pinion angle at ride height?

Yes, you can adjust the pinion angle at ride height. This is particularly important for trucks with a 4-link suspension system, as it allows for more precise adjustments.

How do you set a pinion angle with a 2-piece driveshaft?

Generally, setting a pinion angle with a 2-piece driveshaft involves similar steps as with a single-piece, but additional care must be taken to align both sections of the driveshaft.

How do you know if the pinion angle is off?

Signs that your pinion angle may be off include unusual vibrations, noises from the driveline, and premature wear of U-joints. It’s crucial to address these issues promptly to avoid further complications.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.

![What Year GMC Truck Beds Interchange? [Answered]](https://www.turbochaos.com/wp-content/uploads/2023/12/What-Year-GMC-Truck-Beds-Interchange-768x622.jpg)