How To Install A Truck Tool Box Without Drilling? Explained

Are you looking for How To Install A Truck Tool Box Without Drilling? Installing a truck toolbox without drilling is a smart choice for truck owners. This approach protects the truck bed from potential damage and maintains the vehicle’s resale value. With the right tools and techniques, this installation process can be straightforward and effective. Emphasizing the no-drill method ensures that your truck remains in top condition while adding the practicality of a toolbox.

Key Takeaways

- No-drill installation preserves truck bed integrity.

- Requires specific tools and hardware for a secure fit.

- Suitable for various truck models and toolbox types.

- Enhances truck functionality without compromising value.

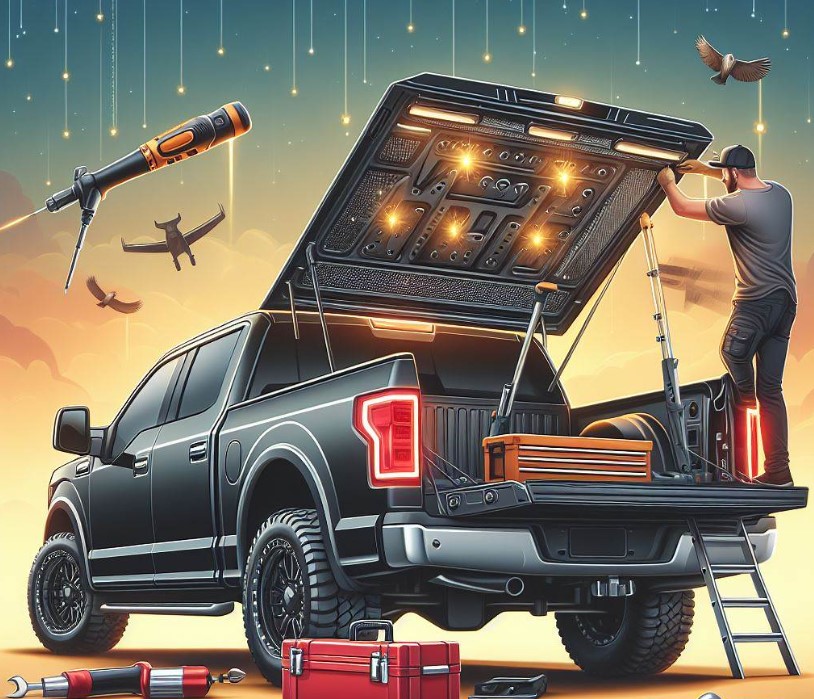

How To Install A Truck Tool Box Without Drilling?

The no-drill installation process involves securing the toolbox to the truck bed using alternative methods. This approach is not only less invasive but also reversible, ideal for those who may want to remove or replace the tool box in the future. It requires a clear understanding of the tools and materials needed for a successful installation.

Tools and Materials Needed

- Non-drilling mounting kit

- Measuring tape

- Marker or chalk

- Weatherproof sealant

- J-hooks or clamps

Step-by-Step Guide

- Choosing the Right Tool Box: Select a toolbox that fits your truck model and storage needs. Consider the material, size, and weight.

- Preparing the Truck Bed: Clean the truck bed and position the toolbox. Mark the placement with a marker or chalk for accuracy.

- Securing the Tool Box: Use J-hooks or clamps from the mounting kit to attach the toolbox to the truck bed’s side rails.

- Weatherproofing: Apply a weatherproof sealant around the edges of the toolbox to prevent water and dust intrusion.

Types of Tool Boxes Suitable for No-Drill Installation

Several types of toolboxes are compatible with the no-drill installation method. It’s crucial to select the right type that aligns with your truck’s design and storage requirements.

Crossover Tool Boxes

- Sit across the truck bed

- Offer ample storage space

- Easy to install with clamps

Side Mount Tool Boxes

- Mounted on the sides of the truck bed

- Provide easy access

- Ideal for smaller tools and equipment

Chest Tool Boxes

- Placed inside the truck bed

- Low-profile design

- Maximizes bed space

No-Drill Mounting Kits: A Closer Look

No-drill mounting kits are essential for this installation process. They typically include J-hooks, clamps, and other hardware that securely attach the toolbox to the truck bed without the need for drilling.

Components of a No-Drill Mounting Kit

- J-hooks or clamps for attachment

- Rubber pads to protect the truck bed

- Weatherproof sealant for added protection

Benefits of Using No-Drill Kits

- Preserves the truck’s structure

- Reversible installation

- Easy to install and remove

Installation Tips and Tricks

Successful installation requires attention to detail and some practical tips. Here are some to ensure your toolbox is securely and correctly installed.

Measuring and Positioning

- Accurately measure the toolbox and truck bed.

- Position the toolbox for optimal access and balance.

Securing the Tool Box

- Tighten the J-hooks or clamps evenly.

- Double-check for any movement or instability.

Weatherproofing

- Apply sealant evenly and allow it to cure.

- Check for any gaps or leaks.

Maintaining Your No-Drill Tool Box

Once installed, maintaining your tool box is crucial for longevity and efficiency. Regular checks and cleaning will ensure it remains in good condition.

Regular Checks

- Inspect the mounting hardware periodically.

- Look for signs of wear or damage.

Cleaning and Upkeep

- Clean the toolbox regularly to prevent rust.

- Lubricate hinges and locks for smooth operation.

How Do You Mount A Toolbox Without Drilling?

Mounting a toolbox without drilling involves using a no-drill mounting kit, which typically includes J-hooks, clamps, and sometimes adhesive pads. First, select a toolbox compatible with your truck’s make and model.

Place the toolbox in the desired position on the truck bed, ensuring it’s centered and aligned properly. Use the clamps or J-hooks provided in the mounting kit to attach the toolbox securely to the truck bed’s side rails.

Ensure the clamps are tightened evenly to prevent the toolbox from shifting. For additional stability and to protect the truck bed’s paint, you can use adhesive pads or rubber mats under the toolbox.

How Do I Secure My Toolbox To My Truck?

Securing a toolbox to your truck effectively requires careful placement and the right hardware. After positioning the toolbox, use the clamps or J-hooks to attach it firmly to the side rails of the truck bed.

Ensure that the toolbox is level and does not obstruct the truck’s rear view or interfere with the opening and closing of the tailgate. Tighten the clamps evenly to avoid any imbalance. For added security, you can use a cable lock or a padlock, attaching it to the toolbox and a secure point on the truck, preventing theft or unwanted removal.

How Do You Bolt Down A Tool Box?

Bolting down a toolbox, though not a no-drill method, provides a more permanent and secure installation. To bolt down a toolbox, you need to first decide on the location and mark where the bolts will go. Drill holes in the toolbox and the truck bed at the marked spots.

Use heavy-duty bolts, nuts, and washers to secure the toolbox to the truck bed. It’s important to ensure that the drilled holes are sealed properly to prevent rust or corrosion. Also, consider the weight distribution in the truck bed to maintain the vehicle’s balance and performance.

How Should A Tool Box Fit On A Truck?

The fit of a toolbox on a truck is crucial for both practicality and safety. The toolbox should be proportionate to the truck bed, leaving enough room for other cargo.

It shouldn’t obstruct the rear view or interfere with the opening and closing of the tailgate. The height of the toolbox should allow for easy access without requiring excessive reaching or bending.

Additionally, the toolbox should not extend beyond the width of the truck bed, as this can cause aerodynamic issues and potentially be a safety hazard. Proper fitting ensures that the toolbox is both a convenient storage solution and safe for road use.

Conclusion

Installing a truck toolbox without drilling is an excellent way to enhance your truck’s functionality without compromising its integrity. By following this guide, you can ensure a secure and efficient installation.

Remember, preserving your truck’s condition is as important as adding practical storage solutions. Embrace this no-drill method for a hassle-free and reversible installation.

People Also Ask

Will a no-drill tool box installation void my truck’s warranty?

In most cases, no-drill installations will void your truck’s warranty as they don’t involve permanent modifications. However, it’s always wise to check your specific warranty terms to be sure.

How do I choose the right no-drill mounting kit?

Choose a mounting kit that’s compatible with both your truck and the toolbox. Look for kits with sturdy construction and all necessary components included. Reading reviews and manufacturer specifications can help in making the right choice.

Can no-drill installations damage the paint on my truck bed?

If not done carefully, there can be some risk of scratching or damaging the paint. To minimize this, use protective rubber pads where the toolbox contacts the truck bed. Also, avoid over-tightening the clamps or J-hooks.

How do I ensure my tool box is weatherproof?

Apply a weatherproof sealant around the edges of the tool box during installation. Ensure the sealant is evenly applied and check for gaps. Additionally, choose a tool box with a weather-resistant design.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.

![2005 Chevy Colorado Transmission Problems [3 Working Solutions]](https://www.turbochaos.com/wp-content/uploads/2023/06/2005-Chevy-Colorado-Transmission-Problems-768x512.jpg)