How Many Gallons Of Coolant Does A Semi Truck Hold? Answered

When it comes to the optimal functioning of semi trucks, understanding the specifics of their coolant systems is vital. So, Are you looking for How Many Gallons Of Coolant Does A Semi Truck Hold? This question, while seemingly straightforward, plays a crucial role in the maintenance and efficiency of these heavy-duty vehicles.

The coolant capacity can vary based on truck model, engine size, and manufacturer specifications. This article dives deep into the nuances of semi-truck coolant systems, providing valuable insights for drivers, mechanics, and enthusiasts alike.

Key Takeaways

- The typical coolant capacity for semi trucks ranges from 10 to 15 gallons.

- Factors influencing coolant capacity include engine size, model, and design.

- Regular maintenance of the coolant system is essential for truck efficiency.

- Understanding specific manufacturer guidelines is crucial for optimal performance.

How Many Gallons Of Coolant Does A Semi Truck Hold?

A semi-truck typically holds between 10 to 15 gallons of coolant. However, this is not a one-size-fits-all figure. The exact capacity depends on various factors such as the engine size, the design of the truck, and manufacturer specifications.

For instance, trucks with larger engines or those designed for heavy-duty applications might require more coolant to maintain optimal engine temperatures.

- Engine Size and Design: Larger engines generally have a higher coolant capacity due to their increased heat output. The design of the truck, especially the cooling system layout, also affects the amount of coolant needed.

- Manufacturer Specifications: Different manufacturers have varying guidelines for coolant capacity. It’s crucial to consult the specific manual for accurate information.

Importance of Coolant in Semi Trucks

Coolant plays an essential role in maintaining the health of a semi truck’s engine. It prevents the engine from overheating and protects it from freezing in cold temperatures. The right amount of coolant ensures the engine operates within the optimal temperature range, which is critical for both performance and longevity.

Understanding Coolant Function

- Heat Regulation: Coolant absorbs the heat generated by the engine and dissipates it through the radiator.

- Corrosion Prevention: Modern coolants include additives that protect engine components from corrosion.

Maintaining Coolant Levels

- Regular Checks: Frequent monitoring of coolant levels helps in the early detection of leaks or other issues.

- Quality of Coolant: Using the correct type and quality of coolant as recommended by the manufacturer is essential.

Coolant System Components in Semi Trucks

A semi truck’s coolant system consists of several key components, each playing a vital role in engine temperature management. Understanding these components helps in effective maintenance and troubleshooting.

Key Components

- Radiator: The primary cooling device that dissipates heat from the coolant.

- Water Pump: Circulates the coolant throughout the engine and the cooling system.

Significance of Each Component

- Thermostat: Regulates the flow of coolant based on engine temperature.

- Hoses and Clamps: Transport coolant and must be in good condition to prevent leaks.

Factors Affecting Coolant Capacity

Several factors influence the amount of coolant a semi-truck requires. Knowing these can help in the accurate maintenance and optimization of the cooling system.

Engine Type and Size

- Larger Engines: Generally require more coolant due to higher heat output.

- Engine Design: Some designs may have intricate cooling channels, affecting coolant volume.

Truck Model and Usage

- Model Specifics: Different truck models have unique cooling system designs.

- Usage: Trucks used in harsher conditions might need more robust cooling solutions.

Maintenance and Upkeep of Coolant Systems

Proper maintenance of the coolant system is vital for the longevity and efficiency of semi-trucks. Regular upkeep prevents breakdowns and ensures smooth operation.

Routine Checks and Maintenance

- Coolant Level and Quality: Regularly check and maintain the correct level and quality of coolant.

- System Inspection: Periodic inspection of the entire cooling system for leaks or wear.

Importance of Regular Maintenance

- Engine Health: A well-maintained coolant system directly impacts engine health and performance.

- Cost-Efficiency: Prevents costly repairs and downtime due to overheating or freezing.

Upgrading and Modifying Coolant Systems

For those looking to enhance their semi truck’s performance, upgrading the coolant system can be a wise investment. Modifications can lead to improved efficiency and reliability.

Potential Upgrades

- High-Performance Radiators: Offer better cooling efficiency.

- Advanced Coolants: Provide better heat transfer and corrosion protection.

Considerations for Upgrading

- Compatibility: Ensure that upgrades are compatible with your truck’s model and engine.

- Professional Advice: Consulting with a professional is recommended for optimal results.

How Much Coolant Does A Freightliner Take?

Freightliner trucks, known for their robustness and efficiency, have varying coolant capacities depending on the model and engine type. On average, a Freightliner truck can hold between 12 to 15 gallons of coolant.

However, this figure can fluctuate based on the specific model and engine configuration. For instance, a Freightliner with a smaller engine might require less coolant compared to one equipped with a larger, more powerful engine.

To determine the exact coolant capacity, it’s advised to refer to the owner’s manual or manufacturer’s specifications for your specific Freightliner model.

How Many Gallons Of Coolant Does A Cummins ISX Hold?

The Cummins ISX engine, commonly used in heavy-duty trucks, typically requires about 10.5 to 12 gallons of coolant. The Cummins ISX is designed for efficiency and power, and its coolant capacity is engineered to match these requirements.

This capacity ensures that the engine maintains an optimal operating temperature and maximizes its performance and longevity. As always, for the most accurate information, it’s best to consult the Cummins ISX engine manual or manufacturer’s documentation.

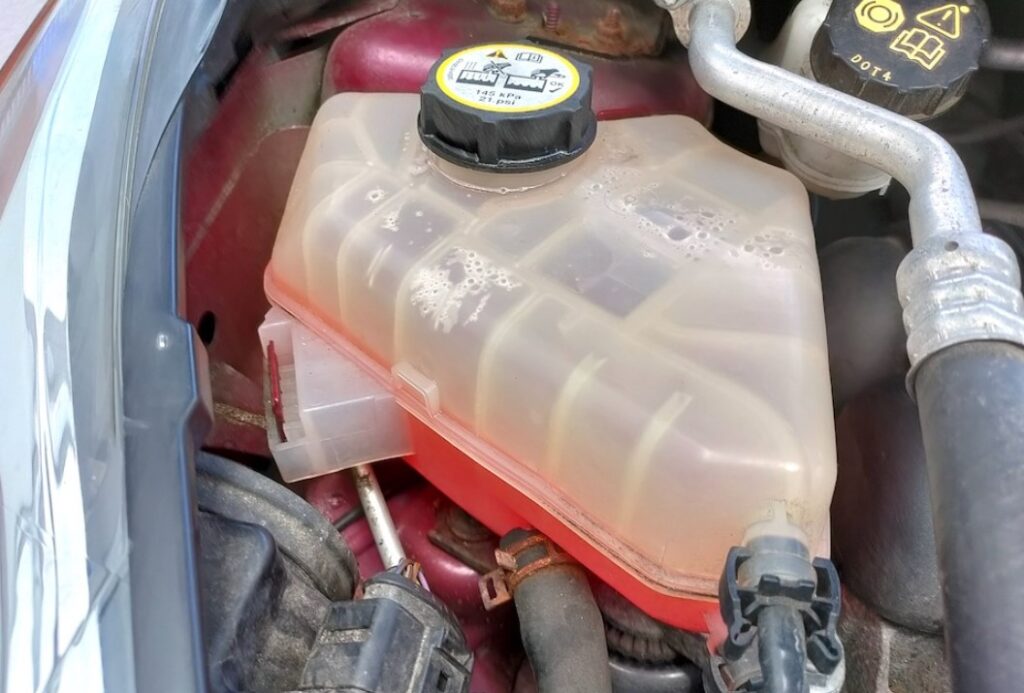

What Kind Of Coolant Does A Semi-Truck Use?

Semi-trucks generally use a heavy-duty coolant specifically formulated for large diesel engines. This type of coolant is designed to handle the high heat and pressure conditions typical in large truck engines.

It often contains additives that prevent rust, corrosion, and foaming, and helps in maintaining engine temperature within safe limits. There are different types of coolants available, including conventional green antifreeze and more advanced formulations like Extended Life Coolants (ELC) that offer longer service intervals and better protection.

The specific type of coolant required can vary based on the truck’s make and model, and it is crucial to use the coolant type recommended by the manufacturer.

Are Coolant And Antifreeze The Same?

Coolant and antifreeze are terms often used interchangeably, but they refer to slightly different substances. Antifreeze is a concentrated, glycol-based liquid that is added to water to make coolant.

Its primary role is to lower the freezing point and raise the boiling point of the coolant, allowing the engine to operate efficiently in extreme temperatures.

When mixed with water, typically in a 50/50 ratio, antifreeze becomes coolant, which circulates through the engine to remove excess heat and prevent freezing. So, while all coolant contains antifreeze, not all antifreeze is directly used as coolant until it is mixed with water.

Do I Need To Change My Antifreeze?

Changing the antifreeze in your semi-truck is an essential part of maintenance. Over time, antifreeze can degrade and lose its effectiveness, leading to a reduced ability to regulate engine temperatures and prevent corrosion.

Most manufacturers recommend changing the antifreeze every 2 to 3 years or after a certain number of miles, typically between 20,000 and 30,000 miles. However, this can vary based on the type of antifreeze used and the specific requirements of your vehicle.

Extended Life Coolants (ELCs) may have longer service intervals. Regular checks of the antifreeze’s condition and concentration are also important to ensure the health and longevity of the engine.

Conclusion

In conclusion, the coolant capacity of a semi-truck, typically ranging from 10 to 15 gallons, is a critical aspect of its maintenance and operation. The exact amount depends on factors like engine size, truck model, and design.

Regular maintenance, understanding the coolant system components, and considering potential upgrades are key to ensuring the longevity and efficiency of the truck.

With careful attention to these details, truck operators can significantly enhance their vehicle’s performance and reliability. Understanding the nuances of semi-truck coolant capacities and maintenance is essential for optimal truck operation.

Top FAQ’s

Are there environmentally friendly coolant options for semi trucks?

Yes, there are eco-friendly coolants available that are made with less toxic and more biodegradable materials. These coolants still provide the necessary protection for the engine but have a reduced environmental impact.

Can a semi-truck operate in extreme temperatures without coolant issues?

A semi-truck can operate in extreme temperatures if it has the correct coolant type and level. The coolant’s antifreeze properties are crucial in cold conditions, while its heat absorption capacity is essential in hot climates.

What happens if a semi-truck runs without enough coolant?

Running a semi-truck with low coolant levels can lead to overheating, which may cause severe engine damage like warped components or a blown head gasket. It can also lead to inefficient fuel consumption and increased emissions.

Is distilled water necessary for mixing with coolant in a semi truck?

Yes, it’s recommended to use distilled water to mix with coolant. Distilled water is free from minerals and impurities that can cause scaling and corrosion in the cooling system.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.

![What Year GMC Truck Beds Interchange? [Answered]](https://www.turbochaos.com/wp-content/uploads/2023/12/What-Year-GMC-Truck-Beds-Interchange-768x622.jpg)