Why Cylinder Heads And Engine Block Not Attached? Explained

In the intricate world of automotive engineering, Why Cylinder Heads And Engine Block Not Attached? is a question that intrigues many. This design choice is rooted in the fundamentals of engine construction and functionality. Understanding this separation is crucial for grasping the dynamics of engine performance, maintenance, and repair.

Key Takeaways

- Separate Manufacturing: Cylinder heads and engine blocks are produced separately for precision and quality control.

- Material Differences: Different materials are often used for heads and blocks to optimize performance.

- Thermal Expansion: Separate components allow for better handling of thermal expansion and contraction.

- Repair and Maintenance: Easier repair and maintenance with separate components.

- Design Flexibility: Flexibility in engine design and upgrading.

Why Cylinder Heads And Engine Block Not Attached?

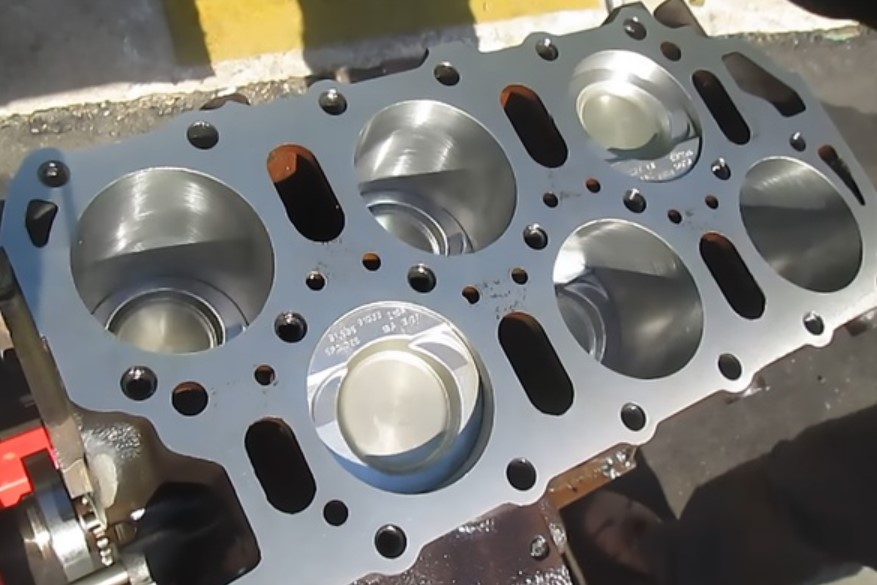

The separation of cylinder heads and engine blocks in an engine is a deliberate and essential design choice. This detachment allows each part to be manufactured with specific materials and methods tailored to their unique functions.

The cylinder head, often made from lighter alloys, is designed for efficient airflow and houses components like valves and spark plugs. The engine block, typically cast from iron or aluminum, forms the robust base of the engine, supporting the crankshaft and pistons.

Material Selection and Manufacturing

The choice of materials for cylinder heads and engine blocks is a critical aspect of their separate construction. Cylinder heads often utilize aluminum alloys for their lightweight and superior heat dissipation properties.

In contrast, engine blocks are generally made from iron or aluminum, with iron being preferred for its strength and durability. The differing material properties necessitate separate manufacturing processes, ensuring each component is optimally designed for its specific role.

Thermal Expansion and Contraction

Engines undergo significant thermal changes, expanding when hot and contracting when cooled. The cylinder head and engine block expand at different rates due to their distinct materials and functions.

This separate construction allows each part to expand and contract without causing undue stress or potential damage to the other, thereby enhancing the engine’s overall durability and lifespan.

Easier Maintenance and Repair

Detaching the cylinder head from the engine block simplifies maintenance and repairs. It allows mechanics to access internal components such as valves, pistons, and gaskets more easily.

This design also makes it feasible to replace or repair only the damaged part, be it the cylinder head or the engine block, without needing to dismantle the entire engine.

Design Flexibility

Separate construction of cylinder heads and engine blocks offers greater flexibility in engine design and potential upgrades. Manufacturers can modify one component without altering the other, facilitating the introduction of new technologies and improvements.

This modularity also enables the same engine block to be used with different cylinder heads, adapting the engine for various applications and performance requirements.

The Role of Gaskets in Engine Construction

A vital component in the interface between the cylinder head and engine block is the gasket. This seal plays a crucial role in maintaining the integrity of the engine’s internal environment.

Importance of Engine Gaskets

Gaskets are essential for creating a tight seal between the cylinder head and engine block. They prevent the leakage of fluids and gases, ensuring efficient combustion and lubrication. The gasket must withstand high temperatures and pressures, making its durability and reliability critical to engine performance.

Types of Gaskets

There are various types of gaskets used in engines, including multi-layer steel, copper, and composite materials. The choice depends on the engine’s design and operational requirements. Multi-layer steel gaskets, for example, are popular for their strength and resilience under high pressure and temperature conditions.

Advantages of Modular Engine Design

The modular design of engines, with separate cylinder heads and blocks, brings several advantages to both manufacturers and users.

Manufacturing Efficiency

Modular engine construction allows for more efficient manufacturing processes. Separate production of cylinder heads and engine blocks can be optimized for each component’s specific requirements. This approach results in better quality control and potentially lower production costs.

Customization and Upgrades

Modularity in engine design enables easier customization and upgrading of engine components. Users can replace or modify cylinder heads for performance enhancements without the need for extensive engine reconfiguration.

Challenges and Solutions in Engine Assembly

While the separation of cylinder heads and engine blocks offers many advantages, it also presents specific challenges in engine assembly and operation.

Ensuring Proper Alignment and Sealing

Proper alignment of the cylinder head and engine block is crucial for optimal engine performance. Any misalignment can lead to leaks, reduced efficiency, and potential engine damage. Precision engineering and careful assembly practices are essential to mitigate these risks.

Handling Differential Expansion

The different expansion rates of cylinder heads and engine blocks require careful consideration in engine design. Engineers must account for these differences to ensure reliable engine performance under varying thermal conditions.

Why Do You Need A 2 Piece Engine?

A 2 piece engine, comprising a separate cylinder head and engine block, is essential for several reasons. First, it allows for better manufacturing precision. Each part can be crafted from different materials suited to their specific functions.

For example, cylinder heads often need to handle high temperatures and house delicate components like valves and spark plugs, making lighter materials like aluminum alloys ideal. In contrast, engine blocks require sturdier materials like iron for structural support.

Secondly, repair and maintenance are more manageable with a 2 piece design. For instance, if a cylinder head is damaged, it can be removed and repaired or replaced without disassembling the entire engine. This design also makes it easier to access internal components such as pistons and crankshafts.

Finally, having separate components helps handle thermal expansion effectively. Different materials in the head and block expand at different rates when heated.

If these parts were a single unit, this could lead to cracks or warping. The 2 piece design allows each part to expand and contract independently, reducing the risk of damage.

Is The Cylinder Head Bolted To The Cylinder Block?

Yes, the cylinder head is bolted to the cylinder block. This connection is crucial to maintain the integrity of the engine’s internal environment. The head gasket, placed between the head and block, ensures a tight seal. This seal is critical for maintaining the compression of the engine’s cylinders and preventing the leakage of coolant and oil.

The bolting process requires precision. Bolts must be tightened to specific torque specifications in a set pattern. This ensures even pressure distribution across the head gasket, preventing leaks and warping. The correct torque and sequence are crucial for the engine’s proper function and longevity.

Why Are Cylinder Heads Removable?

Cylinder heads are designed to be removable for several practical reasons. Primarily, it facilitates easier maintenance and repair. Many engine issues, like valve failures or gasket leaks, occur in the cylinder head. Being able to remove the head simplifies these repairs.

Additionally, removable cylinder heads allow for easier engine modifications and upgrades. Enthusiasts and mechanics can replace a standard head with one that has better airflow, different valve configurations, or improved combustion chamber designs to enhance engine performance.

Finally, in the event of engine failure, a removable cylinder head means you can address issues without needing to replace or extensively dismantle the entire engine. This design feature significantly reduces repair time and costs.

What Separates The Engine Block And Cylinder Head?

The engine block and cylinder head are separated by a critical component called the head gasket. This gasket is designed to seal the internal combustion process and prevent the mixing of engine oil and coolant in the combustion chamber or the engine itself.

The head gasket must withstand high pressures and temperatures, making its durability vital. It is typically made from materials like multi-layer steel, copper, or composite substances, depending on the engine’s requirements. A failing head gasket can lead to significant engine issues, including overheating, loss of power, and contamination of engine oil with coolant.

The design and material of the head gasket are as important as the cylinder head and block since it needs to complement both components’ thermal expansion and contraction rates.

Conclusion

To conclude, Why Cylinder Heads And Engine Block Not Attached? The answer lies in the pursuit of optimal engine performance, efficiency, and versatility. This design choice reflects a careful balance of material properties, thermal dynamics, and engineering practicalities.

The separation not only facilitates better manufacturing, maintenance, and customization but also ensures the longevity and reliability of the engine. As automotive technology evolves, this modular approach continues to prove its value in the ever-advancing world of engine design.

Frequently Asked Questions

Can upgrading a cylinder head improve engine efficiency?

Yes, upgrading to a better-designed cylinder head can improve engine efficiency. Enhancements like improved airflow, better combustion chamber design, and superior valve control can increase power output, improve fuel economy, and reduce emissions.

Why do cylinder heads have cooling fins in air-cooled engines?

In air-cooled engines, cylinder heads are designed with cooling fins which increase the surface area exposed to air. These fins help dissipate the heat generated during combustion, preventing the engine from overheating.

Is it possible to interchange cylinder heads from different engines?

While it’s technically possible, interchanging cylinder heads between different engines is not straightforward. Cylinder heads must match the engine block in terms of dimensions, bolt patterns, and internal passageways. Mismatched components can lead to poor engine performance or mechanical failure.

How does the design of cylinder heads affect engine performance?

The design of cylinder heads significantly impacts engine performance. Features like the shape of the combustion chamber, the flow of air and fuel through the intake and exhaust ports, and the timing and control of the valves all influence how efficiently the engine can breathe, combust fuel, and expel exhaust, thus affecting power output and fuel efficiency.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.