Where To Attach Chain To Pull Engine? Quick Answer

When it comes to engine removal, knowing Where To Attach Chain To Pull Engine? is crucial. This process is not only about having the right tools but also about understanding the weight distribution and securing points of the engine. Attaching the chain correctly ensures safe and efficient engine removal, a task often undertaken during vehicle maintenance or engine replacement.

Key Takeaways

- Identify secure lifting points on the engine.

- Use a leveler for balanced weight distribution.

- Safety should be the primary concern during engine removal.

- Regularly inspect chains and hooks for wear and damage.

Where To Attach Chain To Pull Engine?

To attach a chain to pull an engine, it should be connected at the engine’s designated lifting points. These lifting points are typically reinforced areas specifically designed to handle the engine’s weight.

They are often located near the engine’s center of gravity to ensure a balanced lift. The exact location of these points can vary depending on the engine model and make, so it’s important to consult the vehicle’s service manual for precise information.

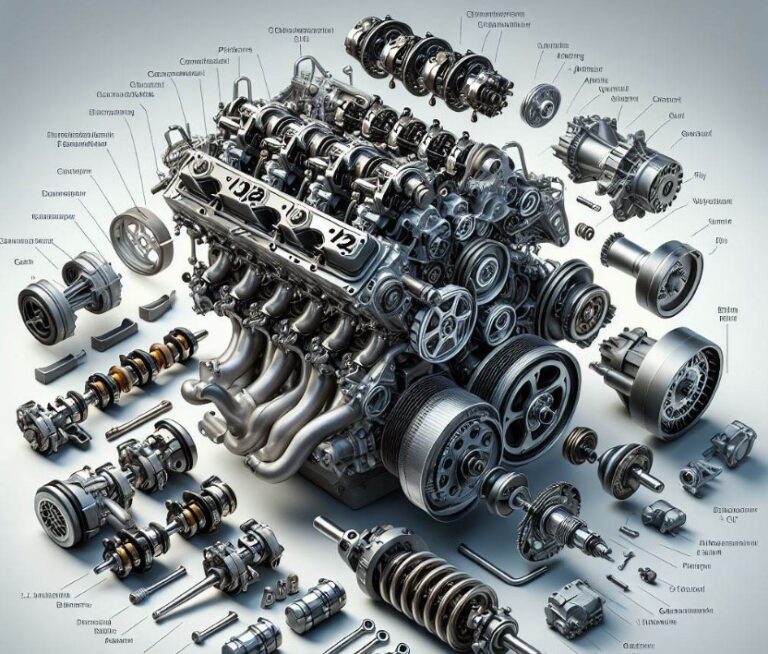

Understanding Engine Anatomy for Secure Attachment

The engine is a complex assembly, and identifying the right points to attach a chain is essential. These points are typically reinforced areas designed to bear the engine’s weight during lifting.

Identifying Lifting Points

Every engine has specific lifting points, usually indicated in the vehicle’s service manual. These points are often near the engine’s center of mass, ensuring a balanced lift. Attaching the chain to non-reinforced areas can lead to damage.

Importance of Engine Service Manual

Consulting the engine service manual provides accurate information on lifting points. Different engines have varying designs, and the manual offers tailored guidance for each model. This step is crucial for preventing damage and ensuring a safe lift.

Best Practices for Attaching the Chain

Attaching the chain correctly is a blend of technique and understanding the engine’s design. Using the right chain and attachments plays a significant role in the safety and efficiency of the process.

Selecting the Right Chain

A high-grade, durable chain is necessary for engine lifting. It should have a weight rating exceeding the engine’s weight and be free from corrosion or damage.

Using Engine Lift Plates

Engine lift plates, when available, offer a secure and easy way to attach the chain. They bolt directly onto the engine, providing reliable lifting points.

Safety Precautions and Gear

Safety is paramount when pulling an engine. The use of protective gear and following safety protocols ensures a risk-free operation.

Personal Protective Equipment (PPE)

Wear safety goggles, gloves, and sturdy footwear. These protect against potential injuries from falling parts or slips.

Checking Equipment Condition

Regular inspection of chains, hooks, and lift equipment is essential. Any signs of wear or damage necessitate immediate replacement to prevent accidents.

Engine Removal Techniques

Removing an engine requires more than just lifting; it involves a series of steps that ensure a smooth and damage-free process.

Step-by-Step Guide to Engine Removal

Follow a systematic approach, starting from disconnecting the battery to removing engine mounts and connections. This ensures that nothing is overlooked, and the engine is safely detached from the vehicle.

Tips for Smooth Engine Removal

Organize your workspace and tools. Label and store removed parts systematically. This organization aids in efficient removal and subsequent reinstallation.

Tools and Equipment Needed

The right tools make engine removal a more manageable task. Investing in quality tools pays off in terms of efficiency and safety.

Essential Tools for Engine Removal

A list of tools, including wrenches, sockets, and screwdrivers, is indispensable. Also, an engine hoist and stand are necessary for safe lifting and handling of the engine.

Renting vs. Buying Equipment

Consider the frequency of use when deciding to buy or rent lifting equipment. For occasional use, renting might be more economical.

Maintenance and Care of Lifting Equipment

Proper maintenance of your lifting equipment extends its life and ensures safety. Regular checks and care are necessary.

Routine Inspection and Maintenance

Regularly inspect chains, hooks, and lifting equipment for signs of wear or damage. Lubricate moving parts and store equipment in a dry, clean place.

Handling and Storage Tips

Proper handling and storage of lifting equipment prevent accidental damage and prolong its usability.

How Do You Lift An Engine With Chains?

Lifting an engine with chains involves several critical steps to ensure safety and efficiency. Firstly, you need to identify the engine’s lifting points, which are usually indicated in the vehicle’s service manual.

These points are designed to handle the weight of the engine during lifting. Once located, attach a high-grade steel chain to these points. The chain should be rated for a weight higher than the engine’s weight. It’s also important to inspect the chain for any signs of wear or damage before use.

An engine leveler attached to the chain can be extremely helpful. It allows you to adjust the angle of the engine as it’s being lifted, providing better balance and control. This is particularly important when navigating the engine out of tight spaces.

When lifting the engine, it’s crucial to do so slowly and steadily. Ensure that all connections to the engine, such as fuel lines and electrical connectors, have been disconnected. As you lift, keep a close eye on the engine and surrounding areas to ensure nothing is obstructing the path or still connected to the engine.

Where Do You Connect An Engine Crane?

Connecting an engine crane correctly is vital for safe engine lifting. The crane should be connected to the engine at its designated lifting points. These points are specifically designed to support the engine’s weight and are typically found near the engine’s center of gravity. This placement ensures that the engine remains balanced during the lift.

Most engines have two or more lifting points, and it’s important to use all of them to distribute the weight evenly. The use of an engine leveler, which attaches to the crane and the chain, allows for fine adjustments to the engine’s angle during lifting, making the process smoother and safer.

Always refer to the vehicle’s service manual for the exact location of these lifting points, as they can vary significantly between different engine types and models. Using the correct lifting points ensures that the engine is lifted safely without risking damage to the engine or surrounding components.

What Is The Best Way To Lift An Engine?

The best way to lift an engine combines safety, efficiency, and the proper use of equipment. The process starts with the preparation of the engine for removal, which includes disconnecting all the connections like fuel lines, and electrical wires, and removing any components that might obstruct the removal process.

Using a high-quality engine crane and chains is essential. The chains should be attached to the engine’s designated lifting points, and an engine leveler should be used to maintain balance.

The engine crane should be positioned so that its arm is centered over the engine. Gradually lift the engine, carefully monitoring the process to ensure the engine remains balanced and that no part of the engine or vehicle is being strained.

Throughout the process, safety should be the top priority. This means using well-maintained equipment, wearing appropriate personal protective equipment, and ensuring that the work area is clear of any obstacles. Additionally, it’s advisable to have an assistant to help monitor the lift and provide guidance as needed.

Conclusion

Attaching the chain to pull the engine requires careful consideration of the engine’s design and lifting points. Using the correct tools, following safety procedures, and understanding the engine’s anatomy are essential for successful and safe engine removal.

Regular maintenance of your equipment ensures its longevity and reliability. Remember, the key to successful engine removal lies in preparation, safety, and the use of the right techniques and tools.

Top FAQ’s

Can lifting points differ between engine models?

Yes, lifting points can vary significantly between different engine models and manufacturers. That’s why it’s crucial to refer to the specific service manual for your engine to locate the correct lifting points.

How often should lifting equipment be inspected?

Lifting equipment should be inspected regularly for signs of wear, corrosion, or damage. This includes checking the chain, hooks, and any other accessories used in the lifting process. It’s advisable to inspect them before each use.

What should I check before lifting the engine?

Before lifting, ensure all connections to the engine (like fuel lines, electrical connectors, and mounts) are disconnected. Check the chain and lifting equipment for any signs of damage or wear, and make sure the engine is properly balanced.

How do I ensure the chain is securely attached?

After attaching the chain to the lifting points, ensure it’s tightly secured and the hooks are correctly closed. The chain should not have excessive slack, and it should be positioned to avoid slipping off the lifting points.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.