What Is The Difference Between A DT466 And A DT466E?

This article will explain What Is The Difference Between A DT466 And A DT466E? The debate between the DT466 and the DT466E engines has been a topic of interest for many in the automotive and trucking industries. These engines, known for their durability and performance, have distinct features and applications. Understanding their differences is crucial for anyone involved in heavy-duty transportation or engine mechanics.

Key Takeaways

- The DT466 and DT466E differ primarily in their electronic control systems.

- The DT466E has improved fuel efficiency and emissions control.

- Both engines are revered for their reliability and longevity in heavy-duty applications.

What Is The Difference Between A DT466 And A DT466E? [DT466 vs DT466E: A Detailed Comparison]

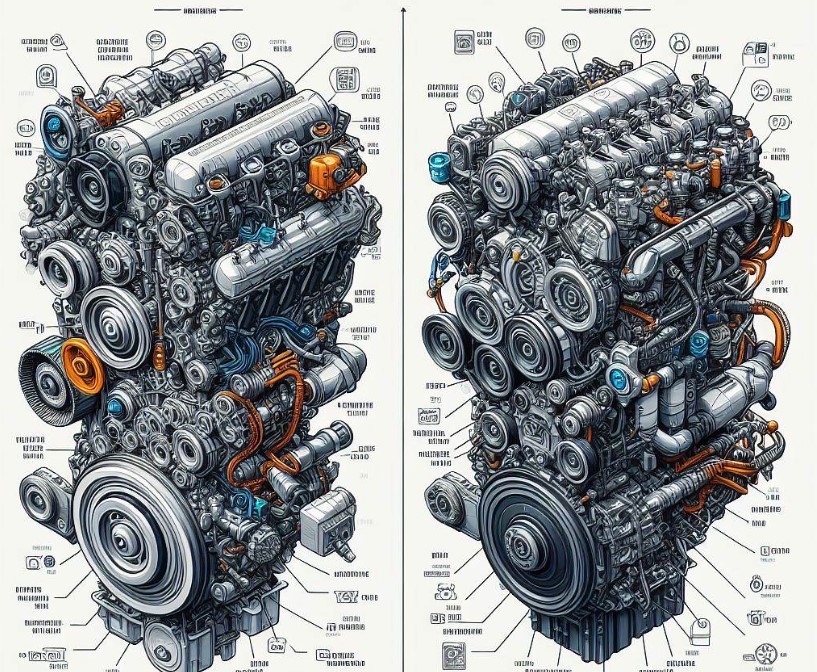

Engine Design and Manufacturing

The DT466 Evolution

The DT466 engine, developed by International Harvester, now Navistar International, is a diesel engine known for its robust performance in heavy-duty vehicles. Introduced in the 1970s, this engine has a mechanical fuel injection system.

The DT466E Evolution

In contrast, the DT466E, where ‘E’ stands for ‘electronic’, was introduced in the late 1990s. It represents an evolution in engine technology with its electronic fuel injection system. This advancement brought about more precise fuel delivery, leading to better efficiency and control.

Performance and Efficiency

Advancements in the DT466

The DT466 engine is renowned for its simplicity and ease of repair. However, it lacks the sophisticated electronic control systems of modern engines.

Advancements in the DT466E

The DT466E stands out with its electronic control module (ECM), which optimizes performance and fuel efficiency. This results in lower emissions, meeting more stringent environmental standards.

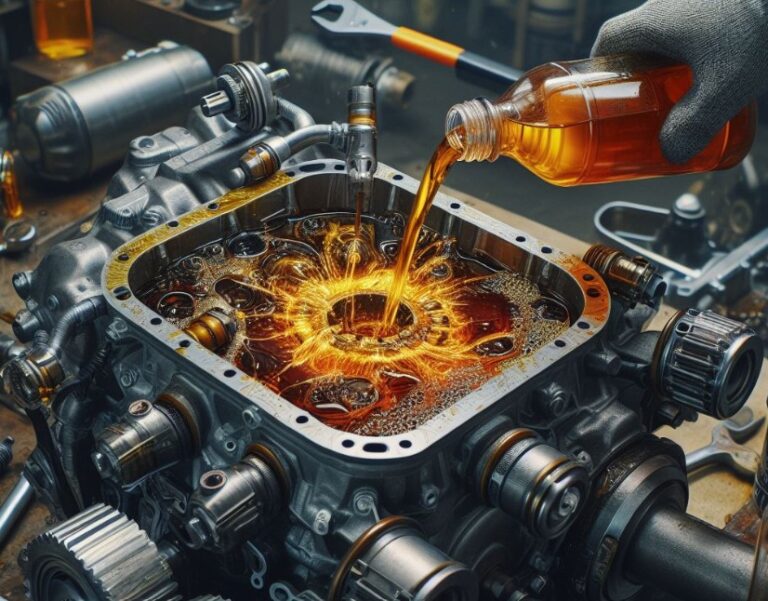

Fuel Injection System

Electronic Control in DT466

The original DT466 uses a mechanical fuel injection system, which is less efficient but more straightforward to maintain and repair.

Electronic Control in DT466E

Conversely, the DT466E’s electronic fuel injection system provides more precise control over the engine’s operations, enhancing overall performance and fuel economy.

Applications and Versatility

DT466 Broader Appeal

Both engines are widely used in a variety of heavy-duty applications, including trucks, buses, and construction equipment.

DT466E’s Broader Appeal

The DT466E, with its improved efficiency and control, has become more popular in environments where fuel economy and emissions are significant concerns.

Maintenance and Longevity

Enhanced Durability in DT466

The DT466’s simpler mechanical systems make it easier and often less expensive to repair.

Enhanced Durability in DT466E

Despite its complexity, the DT466E is designed for durability. Its electronic systems, while more complex, contribute to more efficient operation and potentially longer engine life.

Environmental Impact

DT466E Eco-Friendly Design

The DT466, while robust, does not meet the latest emissions standards.

DT466E’s Eco-Friendly Design

The DT466E, with its advanced electronic controls, is better equipped to reduce emissions, aligning with modern environmental regulations.

Cost Considerations

Investing in the DT466

The DT466 is generally less expensive to purchase and maintain due to its simpler design.

Investing in the DT466E

While the initial cost and maintenance of the DT466E are higher, its efficiency and longevity can lead to long-term savings.

How Does Electronic Fuel Injection Enhance Engine Performance?

Electronic fuel injection (EFI) plays a pivotal role in modern engine technology. Unlike traditional mechanical fuel systems, EFI offers more precise control over the fuel-air mixture. This precision significantly enhances engine performance.

With EFI, the air and fuel mix is regulated more accurately, leading to more efficient combustion. This results in increased power output, improved throttle response, and smoother engine operation.

Furthermore, EFI systems adapt to changes in altitude and temperature more effectively than mechanical systems. This adaptability ensures consistent engine performance under varying environmental conditions.

The feedback loop in EFI systems continuously monitors and adjusts the engine’s operation, ensuring optimal performance at all times. This technology has become a standard in contemporary engine designs due to its numerous advantages in performance and efficiency.

What Are the Advantages of Modern Diesel Engine Technologies?

Modern diesel engine technologies have brought significant improvements in efficiency and environmental impact. Advancements such as turbocharging and intercooling have elevated the power and efficiency of diesel engines.

Turbochargers increase the amount of air entering the engine, allowing for more fuel to be combusted and thus increasing power output. Intercoolers, on the other hand, cool the air compressed by the turbocharger, enhancing combustion efficiency and reducing engine strain.

Another major advancement is the use of cleaner diesel fuels and advanced emission control systems. These technologies reduce the environmental impact of diesel engines by lowering emissions of harmful pollutants.

Particulate filters and selective catalytic reduction systems are now common in modern diesel engines, significantly reducing the output of soot and nitrogen oxides. These advancements not only meet stringent environmental regulations but also improve public perception of diesel engines as a viable and eco-friendly option.

What Impact Do Diesel Engines Have on the Environment?

The impact of diesel engines on the environment has been a topic of much debate and innovation. Historically, diesel engines were known for their high levels of emissions, particularly nitrogen oxides (NOx) and particulate matter (PM).

These pollutants contribute to air quality problems and pose health risks. However, recent advancements in diesel technology have greatly reduced these emissions.

Modern diesel engines are equipped with advanced emission control systems, including diesel particulate filters and selective catalytic reduction technology. These systems capture and break down a significant portion of the harmful emissions.

Additionally, the introduction of ultra-low sulfur diesel fuel has had a positive impact on reducing emissions. This cleaner fuel allows for the use of advanced emission control technologies, which are less effective with higher sulfur content.

The shift towards more eco-friendly diesel technology reflects a growing awareness of environmental issues and a commitment to reducing the ecological footprint of diesel engines.

How Do Diesel Engines Compare to Gasoline Engines in Terms of Efficiency?

Diesel engines are often compared to gasoline engines, particularly in terms of efficiency and performance. One of the key differences lies in the way diesel engines combust fuel. Diesel engines use compression ignition, where the fuel is injected into compressed, hot air in the cylinder, causing it to ignite.

This process is more efficient than the spark ignition used in gasoline engines. Diesel engines typically convert more of the fuel’s energy into mechanical power, leading to higher fuel efficiency and greater torque at lower speeds.

Another factor contributing to the efficiency of diesel engines is their higher compression ratio compared to gasoline engines. This higher compression ratio allows for a more complete combustion of fuel, translating to better fuel economy and more power per liter of displacement.

Additionally, diesel fuel itself contains more energy per liter than gasoline, further enhancing the efficiency of diesel engines. This makes diesel engines particularly suitable for heavy-duty applications and long-distance transportation, where fuel efficiency is paramount.

Conclusion

In conclusion, the choice between the DT466 and the DT466E depends on specific needs and priorities. The DT466 offers simplicity and ease of repair, while the DT466E excels in efficiency, control, and environmental friendliness. Both engines stand as testaments to durable and reliable design, each catering to different aspects of heavy-duty engine requirements.

People Also Ask

What is the impact of engine tuning on a DT466E?

Engine tuning can improve the performance and fuel efficiency of a DT466E engine. However, it should be done by professionals as improper tuning can lead to engine damage, increased emissions, and voiding of the manufacturer’s warranty. Tuning adjustments should consider the engine’s application and operating conditions.

Can DT466E engines be retrofitted for improved emissions?

DT466E engines can be retrofitted with newer emission control technologies like Diesel Particulate Filters (DPFs) and Selective Catalytic Reduction (SCR) systems to reduce emissions. This is often a requirement to comply with newer emission standards.

How does temperature affect the DT466E engine?

Extreme temperatures, both hot and cold, can affect the DT466E engine’s performance. In cold weather, starting issues and thickened oil can occur, while in hot conditions, overheating and increased engine strain are possible. Using the appropriate oil grade and ensuring a well-maintained cooling system can mitigate these issues.

What is the fuel economy of a DT466E engine?

The fuel economy of a DT466E engine varies based on the vehicle and usage but generally ranges from 6 to 8 miles per gallon. Factors like vehicle weight, driving habits, maintenance, and engine tuning can significantly impact fuel efficiency.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.