What Is A Roller Engine Block? A Comprehensive Guide

Understanding What Is A Roller Engine Block? involves delving into the heart of automotive engineering. This unique component revolutionized engine designs with its efficiency and durability. It’s a core element in many modern engines, providing a blend of performance and reliability. Let’s explore this innovative engine block’s facets, functions, and significance.

Key Takeaways

- Definition and overview of a roller engine block.

- Advantages and applications in the automotive industry.

- Comparison with traditional engine blocks.

- Maintenance and longevity aspects.

- Prospects and innovations.

What Is A Roller Engine Block?

A roller engine block is a type of engine block that utilizes roller camshafts and roller lifters. This design significantly reduces friction between the camshaft and lifters, leading to improved engine efficiency, increased performance, reduced wear, and extended engine lifespan.

Historical Evolution of Roller Engine Blocks

Origins and Development

The roller engine block emerged from a need for more efficient and durable engine components. Its inception dates back to the late 20th century, responding to the automotive industry’s demand for better performance and fuel efficiency. This evolution signified a shift from traditional flat-tappet camshafts to roller camshafts, leading to significant changes in engine block design.

Impact on Automotive Engineering

The introduction of roller engine blocks marked a pivotal point in automotive engineering. They offered enhanced performance, reduced friction, and improved fuel efficiency.

This development paralleled advancements in materials science and precision engineering, making roller engine blocks a staple in modern high-performance vehicles.

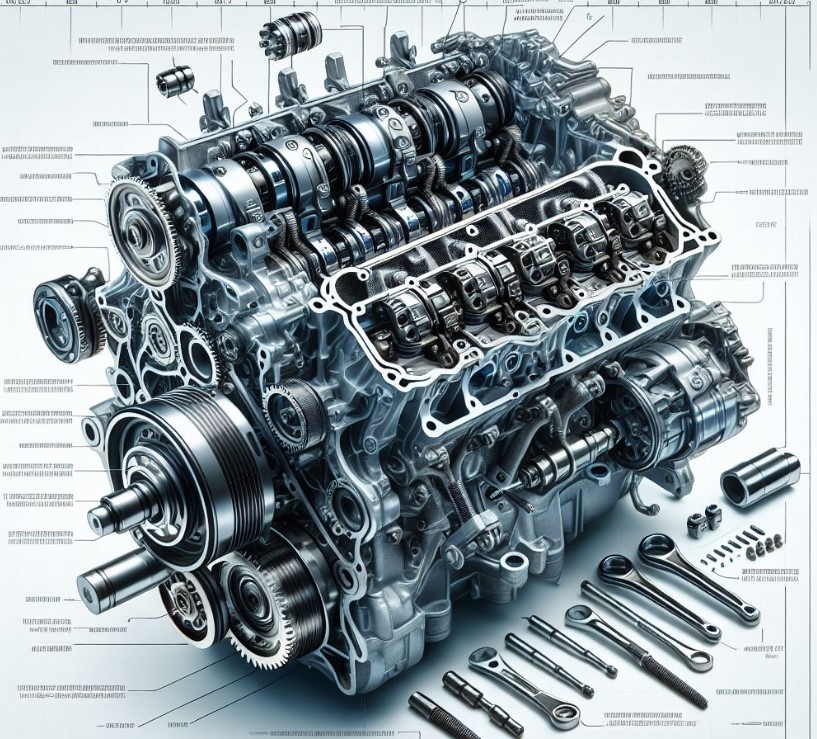

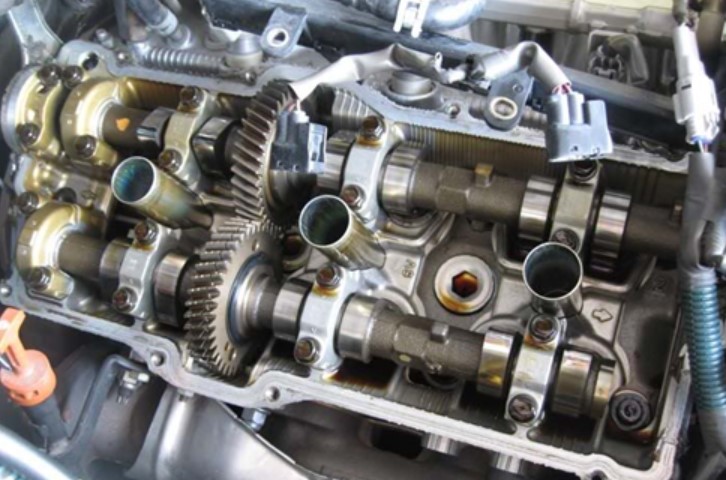

Anatomy of a Roller Engine Block

Core Components and Structure

At its core, a roller engine block consists of several key components: the block itself, roller camshafts, roller lifters, and associated valvetrain elements. Its design is structured to minimize friction and wear, thus enhancing engine life and efficiency.

Functionality and Mechanics

Understanding the functionality of a roller engine block requires a look at its mechanics. The roller camshafts and lifters operate with minimal friction, allowing for smoother operation and better transfer of motion. This design not only improves performance but also contributes to the engine’s overall longevity.

Advantages of Roller Engine Blocks

Enhanced Performance and Efficiency

One of the primary advantages of roller engine blocks is their ability to enhance engine performance. The reduced friction and smoother operation translate to better horsepower and torque output, making them ideal for high-performance applications.

Longevity and Durability

Roller engine blocks are renowned for their longevity. The reduced wear and tear on components means these engines often have a longer lifespan compared to traditional engines. This durability makes them a preferred choice for vehicles that demand reliability.

Roller Engine Blocks in Modern Vehicles

Applications in Various Vehicle Types

Roller engine blocks are not confined to just high-performance cars. They are increasingly found in a variety of vehicles, including trucks, SUVs, and even some hybrid models. Their versatility and efficiency make them suitable for a wide range of automotive applications.

Comparison with Traditional Engine Blocks

Comparing roller engine blocks with traditional ones highlights their advanced nature. Traditional engine blocks, typically with flat-tappet camshafts, often suffer from higher levels of friction and wear. Roller engine blocks, with their modern design, overcome these limitations, offering a more refined and efficient performance.

Maintenance and Upkeep of Roller Engine Blocks

Routine Maintenance Requirements

Like any engine component, roller engine blocks require routine maintenance for optimal performance. Regular oil changes, inspections of the roller components, and timely repairs are essential to maintain their efficiency and longevity.

Impact on Overall Vehicle Maintenance

The reduced wear and tear on roller engine blocks positively impacts overall vehicle maintenance. Vehicles equipped with these engines often require less frequent repairs, translating to lower maintenance costs and extended service intervals.

Future Prospects and Innovations

Technological Advancements

The future of roller engine blocks is tied to ongoing technological advancements. Innovations in materials science and engineering are continually enhancing these engines’ efficiency and performance.

Role in Next-Generation Vehicles

Roller engine blocks are expected to play a significant role in next-generation vehicles. Their efficiency and performance align well with the automotive industry’s push towards more environmentally friendly and fuel-efficient vehicles.

What Is The Difference Between A Roller Block And A Flat Tappet?

The primary difference between a roller block and a flat tappet lies in their camshaft design and operation. A roller block uses roller camshafts equipped with roller lifters or followers, which roll over the cam lobes.

This design significantly reduces friction compared to flat tappet camshafts, where the lifters slide across the cam lobes, creating more friction and wear. Roller blocks typically offer improved efficiency, and reduced wear, and can handle higher RPMs and aggressive cam profiles better than flat tappet engines.

Can I Put A Roller Cam In A Non Roller Block?

Yes, it is possible to install a roller cam in a non-roller block, but it requires modifications. The conversion usually involves changing the lifters, camshaft, and sometimes the timing chain or gears. Specific kits are available for this conversion.

However, it’s essential to ensure compatibility and correct installation, as improper modifications can lead to engine damage. Consulting a professional or referring to manufacturer guidelines is recommended for such conversions.

What Are The Benefits Of A Roller Cam?

Roller cams offer several benefits over traditional flat tappet cams:

- Reduced Friction: The rollers reduce friction between the camshaft and the lifters, leading to smoother operation and less heat generation.

- Increased Performance: They allow for more aggressive cam profiles, which can improve engine breathing and performance.

- Durability: Less friction means less wear, contributing to the longevity of the engine components.

- Improved Fuel Efficiency: Enhanced efficiency in valve operation can lead to better fuel economy.

- Compatibility with Modern Fuels: Roller cams are less susceptible to damage from low zinc and phosphorus levels in modern engine oils, unlike flat tappets that require these additives to prevent excessive wear.

What’s The Difference Between A Roller Block And A Non-Roller Block?

The difference between a roller block and a non-roller block primarily revolves around the type of camshaft and lifters used. Roller blocks use roller camshafts and lifters, which reduce friction and wear within the engine.

Non-roller blocks, on the other hand, use flat tappet camshafts, where the lifters directly slide over the cam lobes, resulting in higher friction and potentially more wear over time.

Roller blocks generally provide better performance, efficiency, and longevity compared to non-roller blocks. The choice between the two often depends on the application, performance requirements, and budget considerations.

Conclusion

In conclusion, the roller engine block represents a significant advancement in automotive technology. Its efficiency, durability, and performance make it an essential component in modern vehicles.

As we move towards a future of innovative automotive solutions, the role of roller engine blocks becomes increasingly crucial, embodying the blend of performance and sustainability that defines contemporary vehicle engineering. This engine block type stands as a testament to the ongoing evolution of automotive engineering.

People Also Ask

How do Roller Engine Blocks Affect Vehicle Longevity?

Vehicles equipped with roller engine blocks often have a longer lifespan. The reduced wear on engine components due to less friction means these vehicles can operate effectively for a more extended period compared to those with traditional engine blocks.

Are Roller Engine Blocks Suitable for High-Performance Vehicles?

Yes, roller engine blocks are particularly suitable for high-performance vehicles. Their design allows for smoother operation, increased horsepower, and better torque output, making them ideal for performance-oriented applications.

How do Roller Engine Blocks Impact Environmental Sustainability?

By improving fuel efficiency and reducing engine wear, roller engine blocks contribute to environmental sustainability. They play a role in reducing emissions and align with the automotive industry’s push towards more environmentally friendly vehicles.

What Maintenance is Required for Roller Engine Blocks?

Routine maintenance for roller engine blocks includes regular oil changes, inspections of the roller components, and timely repairs. Proper maintenance ensures optimal performance and extends the engine’s lifespan.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.

![What Does A Turbo Silencer Ring Do? [Explained]](https://www.turbochaos.com/wp-content/uploads/2023/12/What-Does-A-Turbo-Silencer-Ring-Do-768x694.jpg)

![Is Caterpillar Making Truck Engines Again? [Answered]](https://www.turbochaos.com/wp-content/uploads/2023/12/Is-Caterpillar-Making-Truck-Engines-Again-768x497.jpg)