What Do Reed Valves Do In A 2 Stroke Engine? Explained

Are you looking for What Do Reed Valves Do In A 2 Stroke Engine? This question intrigues many enthusiasts in the automotive and mechanical engineering fields.

Reed valves, integral to the performance of 2-stroke engines, play a crucial role in managing the engine’s air and fuel mixture. Understanding their function not only enhances our technical knowledge but also aids in the maintenance and optimization of 2-stroke engines.

Key Takeaways

- Reed valves control the flow of fuel and air into the combustion chamber of a 2-stroke engine.

- They help in improving engine efficiency and power output.

- Reed valves contribute to better fuel economy and reduced emissions.

- Their design and material composition impact the overall performance of the engine.

What Do Reed Valves Do In A 2 Stroke Engine?

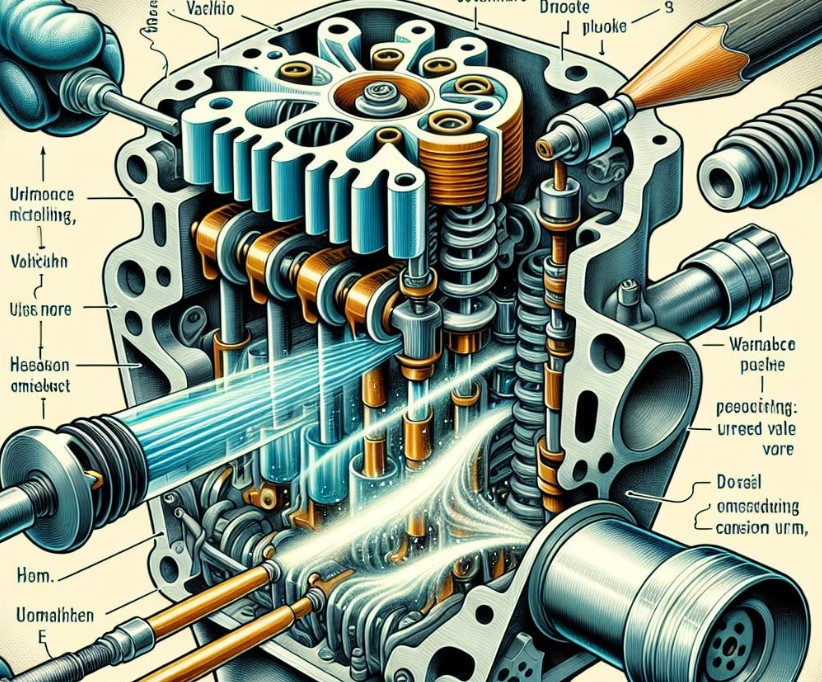

In a 2-stroke engine, reed valves function as one-way gates that control the flow of the fuel and air mixture into the combustion chamber. They open to allow the mixture in and close to prevent it from flowing back into the intake tract, thereby ensuring efficient combustion and improving the engine’s overall performance and efficiency.

The Role of Reed Valves in a 2-Stroke Engine

Functionality and Importance

Reed valves in a 2-stroke engine serve as one-way gates for the air-fuel mixture. These valves ensure that the mixture enters the combustion chamber at the right time and in the right quantity, which is essential for efficient combustion.

The unique characteristic of reed valves is their ability to open and close flexibly based on the engine’s internal pressures. This adaptability optimizes the engine’s breathing process, enhancing both its power output and efficiency.

Impact on Engine Performance

The performance of a 2-stroke engine is heavily dependent on the efficiency of its reed valves. Efficient valves ensure a consistent supply of the air-fuel mixture, which leads to smoother engine operation and increased power.

Moreover, well-functioning reed valves contribute to the engine’s longevity by maintaining optimal internal conditions, thereby reducing wear and tear.

Design and Material of Reed Valves

Influence on Engine Dynamics

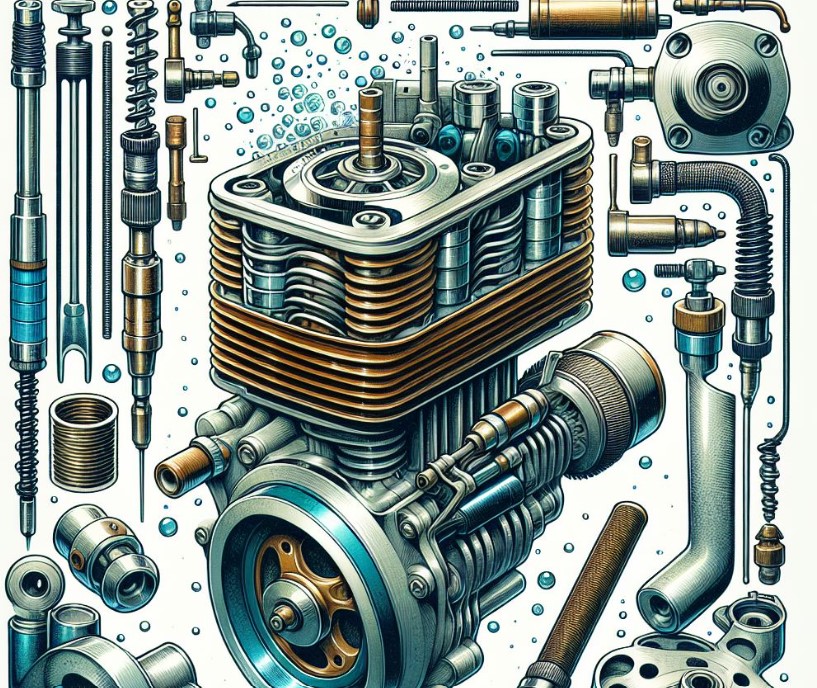

The design of reed valves, including their shape and the material from which they are made, greatly influences the dynamics of a 2-stroke engine.

The valves need to be lightweight yet durable, able to withstand the rapid opening and closing movements during engine operation. Common materials used include fiberglass, carbon fiber, and metal alloys, each offering different performance characteristics.

Evolution and Technological Advances

Over the years, the design and materials of reed valves have evolved significantly. Technological advancements have led to the development of more efficient and durable valves.

Modern reed valves are often custom-designed for specific engine models, taking into account the engine’s size, power output, and intended use. This customization ensures optimal compatibility and performance enhancement.

Impact on Fuel Economy and Emissions

Enhancing Fuel Efficiency

Reed valves contribute to better fuel economy in 2-stroke engines by ensuring a precise mixture of air and fuel. This precision prevents the wastage of fuel, translating to more miles per gallon. Efficient combustion, aided by proper valve function, also means that less fuel is required to produce the same amount of power.

Reducing Emissions

With growing environmental concerns, the role of reed valves in reducing emissions has become increasingly important. By optimizing the combustion process, these valves help in minimizing the release of harmful exhaust gases.

This reduction in emissions is not only beneficial for the environment but also helps engines meet stricter emission regulations.

Reed Valves vs. Other Valve Systems

Comparison with Alternative Systems

Reed valves differ significantly from other valve systems used in 4-stroke engines, such as poppet valves. Unlike poppet valves, which are mechanically operated and timed, reed valves operate purely based on the changing pressures within the engine.

This difference in operation leads to distinct performance characteristics in 2-stroke engines compared to their 4-stroke counterparts.

Pros and Cons

While reed valves offer advantages in terms of simplicity, weight, and cost, they also have limitations. Their performance is highly dependent on the precision of their design and the quality of materials used.

In some cases, reed valves may not provide as tight a seal as mechanical valves, potentially leading to efficiency losses.

Maintenance and Troubleshooting

Regular Maintenance

Regular maintenance of reed valves is essential for the smooth operation of a 2-stroke engine. This maintenance includes periodic inspection for wear and tear, cleaning to remove any debris or buildup, and replacement if the valves are damaged or excessively worn. Proper maintenance ensures that the engine continues to perform at its best.

Common Issues and Solutions

Common issues with reed valves include cracking, warping, or becoming stiff over time. These problems can lead to a decrease in engine performance, irregular idling, or starting difficulties. Timely detection and replacement of faulty valves can prevent more serious engine problems.

What Happens When Reed Valves Fail?

When reed valves fail in a 2-stroke engine, several issues can arise, significantly affecting the engine’s performance. Firstly, the engine may experience reduced efficiency and power output.

This occurs because failed reed valves cannot regulate the fuel-air mixture entering the combustion chamber effectively, leading to incomplete or irregular combustion.

Additionally, failed reed valves may result in the backflow of the mixture, causing rough idling, difficulty in starting the engine, and an overall decline in engine responsiveness.

In severe cases, a complete failure of reed valves can even lead to engine stalling, as the air-fuel balance necessary for the engine’s operation is disrupted.

The most common symptoms of reed valve failure include poor acceleration, loss of power, higher fuel consumption, and unusual noises from the intake area. If left unchecked, this can also lead to more serious engine damage due to improper combustion and overheating.

Do Reed Valves Increase Performance?

Reed valves are known to enhance the performance of 2-stroke engines. They play a crucial role in managing the timing and flow of the fuel-air mixture into the combustion chamber.

Properly functioning reed valves ensure that the mixture is delivered efficiently, leading to better combustion and increased power output. This results in smoother engine operation, improved throttle response, and often, a noticeable increase in acceleration and top-end speed.

Furthermore, the design of reed valves can be optimized to suit specific engine characteristics, which can further enhance performance.

For high-performance applications, reed valves made from advanced materials like carbon fiber provide better resilience and responsiveness under high-speed conditions, thus offering a significant boost in engine performance.

Will Bad Reeds Cause Bogging?

Bad or faulty reed valves can indeed cause bogging in a 2-stroke engine. Bogging refers to a loss of power or hesitation in the engine’s response, particularly noticeable when accelerating.

This issue arises because damaged or worn-out reed valves fail to regulate the flow of the fuel-air mixture properly. When the reed valves do not seal correctly, it can lead to an inconsistent mixture entering the combustion chamber, causing the engine to ‘bog down’ or struggle to maintain power.

In some cases, the engine may also experience difficulties in maintaining steady RPMs, exhibit erratic idling, or even stall.

Addressing the issue typically involves inspecting the reed valves for signs of wear, cracking, or improper seating and replacing them if necessary to restore engine performance.

Why Do 2-Stroke Engines Always Have A Reed Valve?

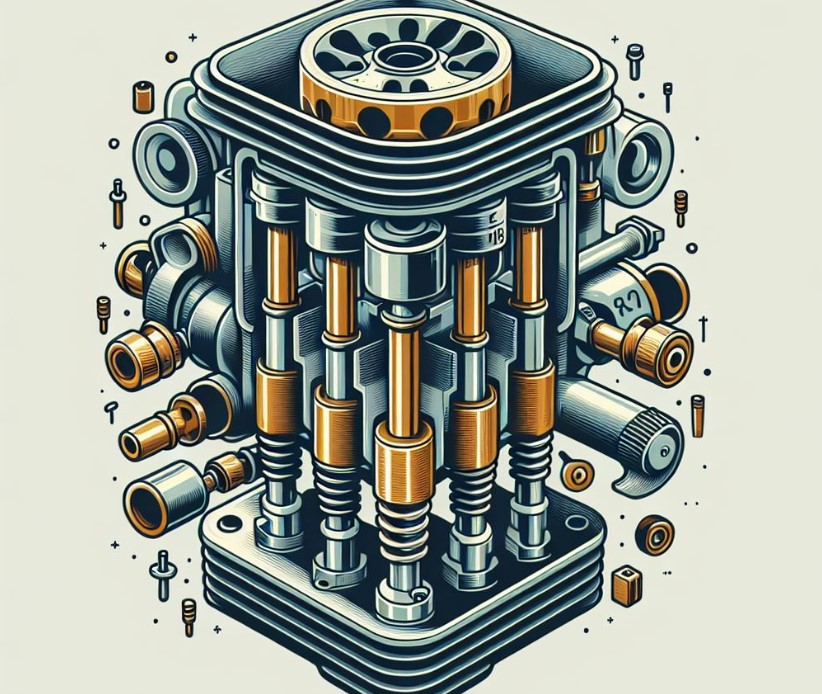

2-stroke engines commonly utilize reed valves due to their simplicity and effectiveness in controlling the intake process. Unlike 4-stroke engines, which use a complex valve train for intake and exhaust processes, 2-stroke engines require a more straightforward mechanism due to their operating cycle.

Reed valves fit this requirement perfectly as they operate based on the pressure changes within the engine, opening to allow the fuel-air mixture in and closing to prevent it from escaping back into the intake.

Their design allows for a continuous and controlled flow of the mixture, which is essential for the 2-stroke engine’s operation, where intake and exhaust occur in a single crankshaft revolution.

The use of reed valves also contributes to the compact and lightweight design of 2-stroke engines, which is particularly advantageous in applications like motorcycles, chainsaws, and outboard motors.

Conclusion

To conclude, What Do Reed Valves Do In A 2 Stroke Engine? They are vital components that significantly influence the performance, efficiency, and environmental impact of the engine.

Their design, material, and condition play a critical role in the overall functioning of 2-stroke engines. Understanding and maintaining these valves is essential for anyone interested in automotive mechanics, particularly those working with 2-stroke engines.

Frequently Asked Questions

Are there any maintenance tips for reed valves in 2-stroke engines?

Regular inspection and cleaning of reed valves are essential. Ensure that they are free from debris and buildup. If the valves are cracked, warped, or stiff, they should be replaced. Using the correct type and quality of fuel and oil can also prolong their life.

Can reed valves influence the emission levels of a 2-stroke engine?

Reed valves play a role in controlling emissions. By regulating the air-fuel mixture and ensuring efficient combustion, they help reduce the emission of unburnt hydrocarbons and other pollutants, making the engine more environmentally friendly.

Do reed valves have an impact on fuel economy?

Yes, reed valves can impact fuel economy. Efficiently functioning reed valves ensure a proper mixture of fuel and air, leading to complete combustion. This not only improves engine performance but also maximizes fuel efficiency.

What are the signs of failing reed valves in a 2-stroke engine?

Signs of failing reed valves include reduced engine performance, difficulty in starting, erratic idling, and in some cases, an increase in fuel consumption. A visual inspection can often reveal cracks, breaks, or warping in the valves.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.