Wastegate Vs Non Wastegated Turbo [All You Need To Know]

In the world of automotive performance, turbochargers play a pivotal role. Among turbochargers, the debate between a Wastegate Vs Non Wastegated Turbo is a topic of keen interest. These two types of turbos differ significantly in terms of their operation, efficiency, and suitability for different applications. This article delves into these differences, providing a comprehensive understanding of each type, their pros and cons, and which might be the best fit for your needs.

Key Takeaways

- Wastegate Turbos regulate boost pressure, offering better control and efficiency.

- Non-Wastegated Turbos are simpler but less efficient in managing boost.

- Wastegate turbos are ideal for high-performance applications.

- Non-Wastegated turbos are better suited for applications where simplicity and cost are priorities.

- Understanding the specific needs of your vehicle is crucial in choosing the right turbo.

Wastegate Vs Non Wastegated Turbo

| Feature | Wastegate Turbo | Non-Wastegated Turbo |

|---|---|---|

| Boost Control | Precise control through the Wastegate valve. | Limited control, dependent on exhaust flow and design. |

| Complexity | More complex due to additional components (Wastegate). | Simpler design with fewer components. |

| Cost | Generally more expensive. | More cost-effective due to simpler design. |

| Performance | Higher performance, ideal for precision applications. | Adequate performance for less demanding applications. |

| Risk of Overboosting | Lower risk due to controlled boost pressure. | Higher risk of overboosting without regulated control. |

| Fuel Efficiency | Potentially more fuel-efficient due to optimized boost. | Less efficient in comparison. |

| Installation | More complex and potentially costlier. | Easier and less expensive to install. |

| Maintenance | Might require more maintenance due to complexity. | Generally requires less maintenance. |

| Turbo Lag | Often reduced due to efficient exhaust management. | Potentially higher turbo lag. |

| Suitability | Preferred for high-performance and precision needs. | Suitable for budget-conscious and simpler applications. |

Wastegate Turbochargers: Precision and Performance

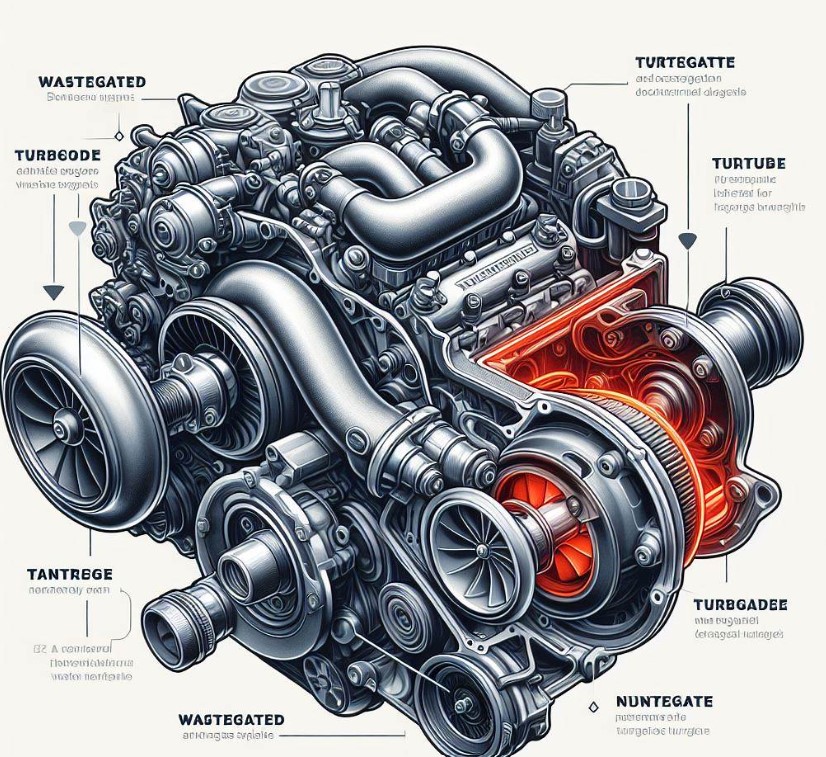

Overview of Wastegate Turbos

A Wastegate turbocharger is equipped with a mechanism called a wastegate. This component is crucial in regulating the turbo’s boost pressure. By opening or closing the wastegate valve, exhaust gases can either be directed through the turbo or bypass it.

This level of control prevents over-boosting and potential engine damage, making Wastegate turbos a popular choice for performance enthusiasts.

Advantages of Wastegate Turbos

- Enhanced Control: The ability to regulate boost pressure allows for a more efficient engine performance.

- Reduced Turbo Lag: With better control over exhaust flow, Wastegate turbos often experience less turbo lag.

- Prevention of Overboosting: The wastegate valve plays a critical role in preventing engine damage due to overboosting.

Disadvantages of Wastegate Turbos

- Complexity: The addition of a wastegate system adds complexity to the turbocharger.

- Cost: Generally, Wastegate turbos are more expensive than their non-wastegated counterparts.

Non-Wastegated Turbochargers: Simplicity and Cost-Effectiveness

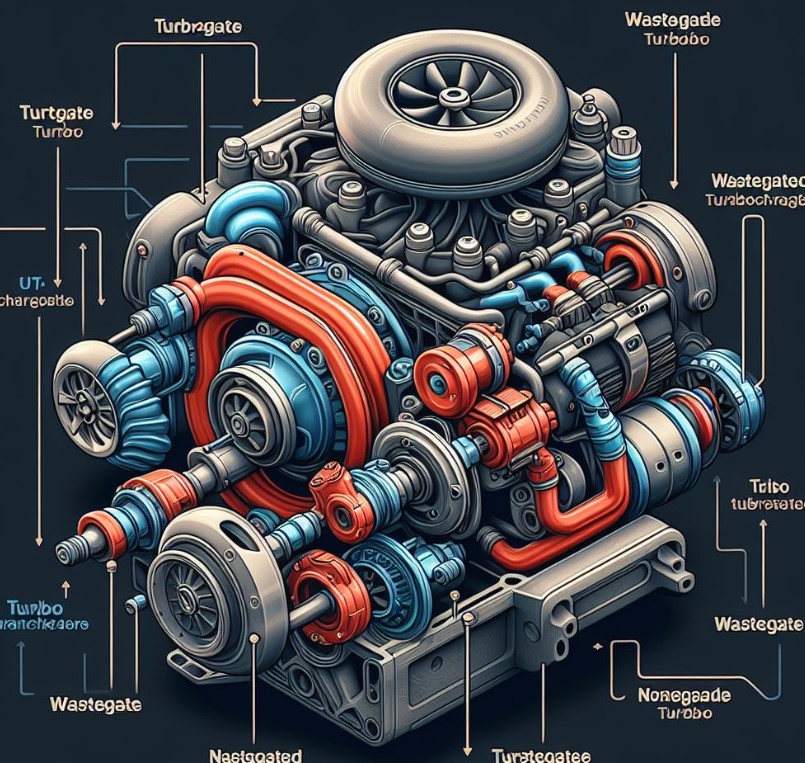

Understanding Non-Wastegated Turbos

Non-Wastegated turbochargers, as the name suggests, do not feature a wastegate. This design simplicity makes them less expensive and easier to install. However, the lack of a wastegate means that these turbos cannot actively regulate boost pressure.

Benefits of Non-Wastegated Turbos

- Simplicity: Fewer components mean easier installation and maintenance.

- Cost-Effective: Generally, non-wastegated turbos are more affordable.

Drawbacks of Non-Wastegated Turbos

- Limited Boost Control: Without a wastegate, controlling the boost pressure is more challenging.

- Potential for Overboosting: The lack of regulation can lead to overboosting and engine damage in extreme cases.

Comparing Performance and Suitability

Performance Analysis

In terms of performance, Wastegate turbos generally outshine non-wastegated ones. The precise control over boost pressure allows for optimized engine performance and efficiency.

However, for applications where simplicity and cost are more critical than peak performance, non-wastegated turbos can be a suitable choice.

Suitability for Different Applications

- High-Performance Vehicles: Wastegate turbos are often the preferred choice due to their precise boost control.

- Budget-Conscious Applications: For those prioritizing cost and simplicity, non-wastegated turbos are more suitable.

Impact on Fuel Efficiency and Emissions

Fuel Efficiency Considerations

Wastegate turbos, with their ability to regulate boost pressure efficiently, can contribute to improved fuel economy. This efficient management of exhaust gases translates to better overall engine performance.

Emissions and Environmental Impact

Both types of turbos have the potential to reduce emissions by optimizing engine efficiency. However, Wastegate turbos, with their precise control, may have a slight edge in reducing harmful emissions.

Installation and Maintenance: A Practical Perspective

Installation Complexity

Installing a Wastegate turbocharger is generally more complex due to the additional components. This complexity can translate to higher installation costs and the need for more specialized knowledge.

Maintenance Requirements

While non-wastegated turbos are simpler and might require less maintenance, the complex nature of Wastegate turbos means they might need more regular maintenance checks to ensure optimal performance.

Difference Between Wastegated and Non-Wastegated Turbos

The primary difference between wastegated and non-wastegated turbos lies in the mechanism used to control the boost pressure generated by the turbocharger.

A wastegated turbo includes a Wastegate valve, either internal or external, that regulates the flow of exhaust gases to the turbo. This valve allows excess exhaust gas to bypass the turbo, preventing over boosting and protecting the engine. In contrast, a non-wastegated turbo lacks this valve.

It relies solely on the engine’s exhaust flow and turbo design to manage the boost. This simplicity can be advantageous in terms of cost and maintenance but offers less precision in controlling the turbo’s boost pressure.

Is a Wastegate Necessary on a Turbo?

Whether a Wastegate is necessary on a turbo depends on the application and the desired level of control over the engine’s performance. In high-performance or precision applications, a Wastegate is essential.

It provides critical control over boost pressure, protecting the engine from damage due to overboosting and optimizing performance.

For less demanding applications where simplicity and cost are more significant factors, a non-wastegated turbo may be sufficient. However, it’s important to note that for modern, high-performance engines, a Wastegate is almost always recommended to ensure reliable and efficient operation.

What Happens If You Run a Turbo with No Wastegate?

Running a turbo without a Wastegate, especially in high-performance applications, can lead to several potential issues. The most significant risk is over boosting, where the turbo generates too much boost pressure.

This excessive pressure can cause engine knock, damage to internal engine components, and potentially lead to catastrophic engine failure.

Additionally, without a Wastegate, there is less control over the turbo’s boost response, which can result in inconsistent performance and increased turbo lag. The turbo and engine setup must be carefully balanced if a non-wastegated turbo is used.

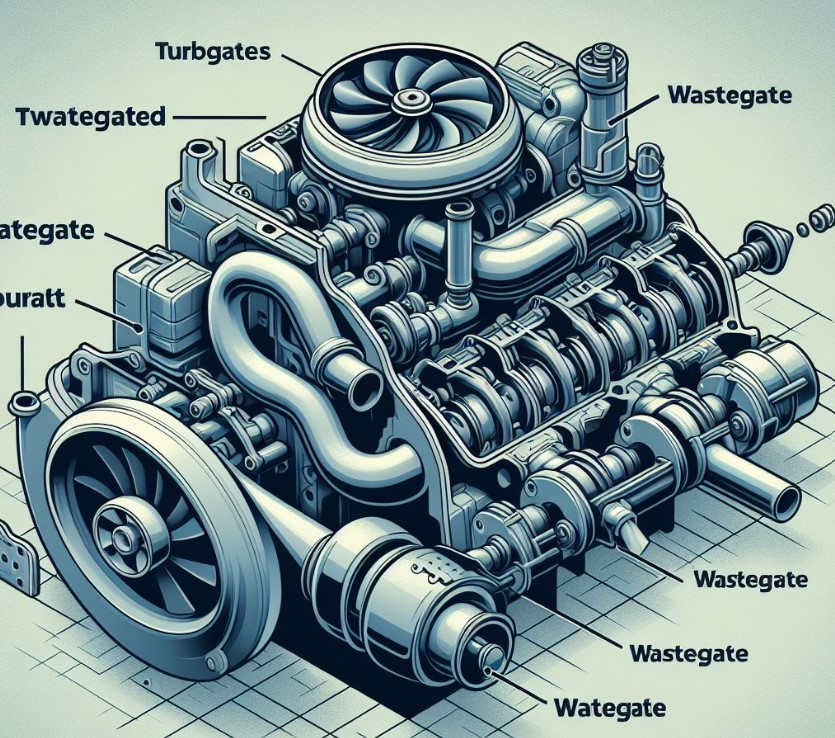

Are Internal Wastegates Better?

Whether internal wastegates are better depends on the specific application and requirements of the vehicle. Internal wastegates are more compact, as they are built into the turbocharger housing, making them a popular choice for OEM applications where space is limited.

They are also generally simpler and cheaper to install. However, external wastegates offer greater precision in boost control and can handle higher levels of exhaust flow, making them ideal for high-performance and racing applications.

External wastegates also allow for easier adjustments and can contribute to a more efficient turbo system by reducing exhaust backpressure. Ultimately, the choice between internal and external wastegates should be based on the specific needs of the engine and the goals of the user.

Conclusion

Choosing between a Wastegate and a Non-Wastegated Turbo boils down to your specific needs and priorities. Wastegate turbos offer precision and performance, ideal for high-performance applications.

In contrast, non-wastegated turbos are more about simplicity and cost-effectiveness, suitable for less demanding applications. Understanding these differences is key to making an informed decision that aligns with your vehicle’s requirements and your performance goals.

People Also Ask

Do Non-Wastegated Turbos Require More Maintenance?

Not necessarily. Non-wastegated turbos are simpler with fewer moving parts, which can sometimes translate to lower maintenance needs. However, the key to turbo longevity, regardless of type, is regular maintenance and correct operation within the engine’s capabilities.

How Does a Wastegate Improve Turbo Performance?

A Wastegate improves turbo performance by precisely controlling the amount of exhaust gas flowing through the turbo. This control helps optimize boost pressure, improving engine efficiency, reducing turbo lag, and preventing overboosting.

Are Wastegated Turbos Suitable for All Types of Vehicles?

Wastegated turbos are suitable for a wide range of vehicles, especially those requiring precise performance tuning, like performance cars and heavy-duty applications. However, for simpler, cost-effective applications, a non-wastegated turbo might be more suitable.

Can Non-Wastegated Turbos Cause Engine Damage?

While it’s less common, non-wastegated turbos can potentially cause engine damage due to overboosting if not properly matched to the engine’s capacity and if there’s no other form of boost control.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.