How Does A Murphy Switch Work On A Diesel Engine? 8 Steps

This article will explain How Does A Murphy Switch Work On A Diesel Engine? In the realm of diesel engines, safeguarding the heart of the machine is paramount. The Murphy Switch, a vital component, plays a crucial role in this protection.

Acting as a sentinel, it monitors various engine parameters. When these parameters deviate from normal, the Murphy Switch springs into action, averting potential engine catastrophes. Its significance cannot be overstated, especially in heavy-duty diesel engines where reliability is key.

Key Takeaways

- A Murphy Switch is a safety device in diesel engines.

- It monitors critical engine parameters.

- Automatic engine shutdown when abnormal conditions are detected.

- Essential for preventing engine damage.

How Does A Murphy Switch Work On A Diesel Engine?

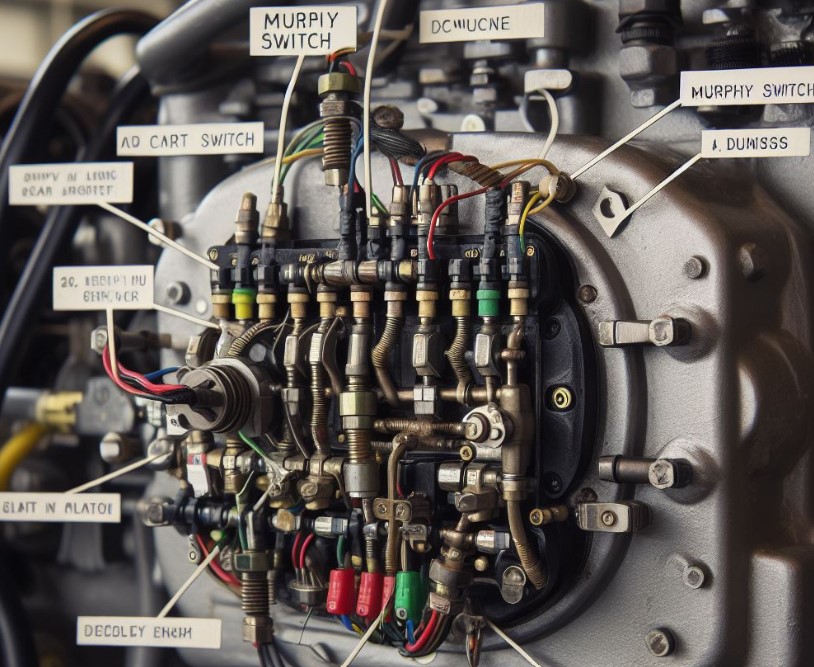

The Murphy Switch is an essential safety component in diesel engines, designed to monitor and respond to critical engine conditions. Here’s a detailed breakdown of how it functions:

- Installation and Connection to Engine Sensors:

- Initially, the Murphy Switch is installed and connected to various sensors on the diesel engine. These sensors are strategically placed to measure vital parameters such as oil pressure, engine temperature, and rotational speed (RPM).

- The switch is wired to these sensors, ensuring it receives real-time data from different parts of the engine.

- Setting Thresholds:

- Once installed, thresholds for each monitored parameter are set. These thresholds are critical values that, if exceeded or not met, indicate potential engine problems. For instance, a specific temperature might be set as the maximum safe operating temperature.

- Real-Time Monitoring:

- The Murphy Switch continuously receives data from the connected sensors during engine operation. It actively monitors these inputs, comparing them against the pre-set thresholds.

- This monitoring is crucial for early detection of any parameter that goes out of the safe operating range.

- Detecting Anomalies:

- If any parameter, like oil pressure or temperature, deviates from its safe range (either too high or too low), the Murphy Switch detects this anomaly. This is the critical point where the switch’s functionality is most vital.

- Triggering a Response:

- Upon detecting an anomaly, the Murphy Switch triggers a response. This response can be configured based on the engine’s requirements and the nature of the monitored parameter.

- The most common responses are activating an audible or visual alarm to alert the operator or initiating an automatic engine shutdown.

- Automatic Engine Shutdown:

- In cases where immediate action is required to prevent engine damage or a safety hazard (like extreme overheating or critically low oil pressure), the Murphy Switch can automatically shut down the engine.

- This shutdown is a safety measure, designed to prevent catastrophic engine damage or accidents.

- Resetting or Manual Override:

- After the Murphy Switch has performed its function, it may require resetting, especially if it has initiated an engine shutdown.

- Some systems may also include a manual override feature, allowing operators to bypass the switch in certain situations.

- Maintenance and Checks:

- Regular maintenance checks are necessary to ensure the Murphy Switch continues to operate correctly. This includes inspecting the connections, verifying the accuracy of the sensors, and ensuring the thresholds are set appropriately for the engine’s operating conditions.

Each of these steps is crucial in ensuring the Murphy Switch performs its role effectively, enhancing the safety and reliability of diesel engines in various applications.

Understanding the Murphy Switch

Functionality and Design

The Murphy Switch, essentially a safety device, is ingeniously designed for diesel engines. It functions by monitoring critical engine parameters like oil pressure, temperature, and engine speed.

If these parameters exceed or fall below pre-set thresholds, the switch activates. This activation can either trigger an alarm or shut down the engine automatically, preventing damage.

Types of Murphy Switches

Murphy Switches come in various types, each tailored to specific engine needs. Common types include pressure switches, temperature switches, and magnetic switches. These variations ensure a wide range of engine parameters can be effectively monitored.

Role in Engine Protection

Preventing Engine Damage

The primary role of a Murphy Switch is to protect the diesel engine from damage. By monitoring essential parameters, it can detect issues like overheating, low oil pressure, or overspeed before they cause serious harm. This early detection is crucial in maintaining engine health and longevity.

Enhancing Safety

Beyond protecting the engine, the Murphy Switch also enhances overall safety. For example, in industrial settings, an engine failure can pose risks to personnel and equipment. The switch’s ability to promptly shut down the engine in abnormal conditions mitigates these risks significantly.

Installation and Maintenance

Installation Process

Installing a Murphy Switch requires technical know-how and precision. It involves connecting the switch to the engine’s sensor systems and configuring it according to the engine’s specifications. Proper installation is vital for the switch to function correctly.

Maintenance Considerations

Like any component, the Murphy Switch needs regular maintenance to ensure its reliability. This includes routine checks, cleaning, and calibration. Maintenance ensures the switch remains sensitive and responsive to engine conditions.

Common Applications

Industrial and Marine Engines

Murphy Switches are widely used in industrial and marine diesel engines. In these applications, engine reliability and safety are of utmost importance. The switch’s ability to prevent engine failures makes it a staple in these sectors.

Agricultural and Mining Equipment

In agriculture and mining, equipment downtime can be costly. Murphy Switches are crucial in these environments, ensuring that machinery operates safely and efficiently, minimizing downtime, and maximizing productivity.

Integration with Engine Control Systems

Compatibility with Modern Engines

Modern diesel engines come equipped with sophisticated control systems. The Murphy Switch integrates seamlessly with these systems, providing an extra layer of protection. Its compatibility with modern technology makes it a relevant and vital component in contemporary engine designs.

Enhancing Engine Performance

Apart from safety, the Murphy Switch also contributes to enhancing engine performance. By preventing damage and downtime, it ensures that engines operate at optimal efficiency. This integration is a testament to the switch’s multifaceted benefits.

What Is The Purpose Of The Murphy Switch?

The Murphy Switch serves a critical role in diesel engine safety and efficiency. Its primary purpose is to monitor various engine parameters such as oil pressure, coolant temperature, and engine rotational speed (RPM).

When these parameters deviate from predefined safe ranges, the Murphy Switch activates a response. This response can range from triggering an alarm to an automatic shutdown of the engine. The switch acts as a proactive safety measure, preventing potential engine damage due to operational anomalies like overheating, low oil pressure, or excessive RPM.

This protection is crucial, especially in industrial, marine, agricultural, and mining applications where engine reliability and safety are paramount. By ensuring these engines operate within safe parameters, the Murphy Switch contributes significantly to the longevity and efficiency of diesel engines.

What Is A Murphy Gauge?

A Murphy Gauge is a specialized instrument commonly used in conjunction with Murphy Switches in diesel engine applications. It is designed to display critical engine parameters such as oil pressure, engine temperature, and fuel level.

These gauges can be analog or digital, providing real-time data to operators, and ensuring they are aware of the engine’s operational status. Murphy Gauges are known for their accuracy, durability, and reliability, making them suitable for harsh operating environments.

They often incorporate features like alarms or shutdown capabilities when linked with a Murphy Switch, enhancing the overall safety and monitoring system of the engine. In summary, Murphy Gauges serves as the visual component of the engine’s monitoring system, offering operators immediate insight into engine performance and condition.

How Does Murphy Switch Work?

The operation of a Murphy Switch is based on real-time monitoring and response to changes in engine parameters. It is typically connected to sensors placed at strategic points on the engine, such as near the oil filter for oil pressure, around the cooling system for temperature, and on the engine block for RPM.

When a parameter like oil pressure drops below or a temperature exceeds set safety thresholds, the switch is triggered. This trigger can activate an alarm, alerting the operator to the abnormal condition.

More critically, it can initiate an automatic shutdown of the engine to prevent damage or hazardous situations. The switch can be configured to respond to a single critical condition or multiple conditions simultaneously.

Its effectiveness lies in its ability to provide immediate and automatic response to engine conditions, which might otherwise go unnoticed until causing significant damage or failure.

Conclusion

The Murphy Switch is an indispensable tool in the arsenal of diesel engine protection. Its ability to monitor, detect, and act upon critical engine parameters makes it a guardian of engine integrity. With various types and applications, it adapts to a range of diesel engines, safeguarding their operation in diverse environments.

The integration of the Murphy Switch in modern diesel engines not only enhances safety but also boosts performance, making it a key component in the efficient and safe operation of these engines.

People Also Ask

Are Murphy Switches used only in industrial and marine diesel engines?

While commonly used in industrial and marine settings, Murphy Switches are also applicable in agricultural, mining, and other environments where diesel engine reliability and safety are critical.

What happens if a Murphy Switch fails?

If a Murphy Switch fails, it may not properly monitor and respond to critical engine conditions, potentially leading to engine damage. Regular maintenance helps prevent switch failure.

Is it possible to adjust the settings of a Murphy Switch?

Yes, many Murphy Switches allow for adjustable settings, enabling customization for specific engine requirements. Adjustments should be made by a qualified technician to ensure accuracy.

Does the installation of a Murphy Switch affect engine warranty?

This depends on the engine manufacturer’s policy. It’s advisable to check with the manufacturer before installation. In most cases, if installed correctly, it should not affect the warranty.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.