How Much Does It Cost To Rebuild A DD15 Engine? [Answered]

Are you looking for How Much Does It Cost To Rebuild A DD15 Engine? Rebuilding a DD15 engine is a significant undertaking, often considered both a necessary and a wise investment for truck owners and fleet managers.

The DD15, known for its efficiency and reliability, is a staple in the commercial trucking industry. However, like all engines, it requires meticulous maintenance, and eventually, a rebuild. Understanding the costs involved in this process is crucial for effective budgeting and decision-making.

Key Takeaways

- Average cost range for a full DD15 engine rebuild.

- Factors influencing the rebuilding cost.

- Comparison with the cost of buying a new engine.

How Much Does It Cost To Rebuild A DD15 Engine?

The cost to rebuild a DD15 engine typically ranges from $20,000 to $30,000. This estimate includes the cost of parts and labor but can vary depending on the extent of the rebuild and the specific service provider.

Understanding the Cost of Rebuilding a DD15 Engine

When considering a rebuild, the first question that comes to mind is, “How much does it cost to rebuild a DD15 engine?” The answer varies based on several factors, including the extent of damage, parts required, and labor costs.

On average, a full rebuild can cost anywhere from $20,000 to $30,000. This range, however, can fluctuate based on your specific needs and circumstances.

Factors Influencing the Rebuilding Cost

Labor Costs

Labor is a significant component of the overall expense. The complexity of the DD15 engine requires skilled technicians and their expertise comes at a price. Rates can vary significantly from one service center to another.

Parts and Materials

The cost of parts is another major factor. Depending on the condition of the engine, you might need to replace various components, ranging from minor parts like gaskets to major ones like the crankshaft or cylinder head.

Comparison with New Engine Costs

Sometimes, truck owners consider purchasing a new engine as an alternative to rebuilding. A new DD15 engine can cost significantly more than a rebuild, often exceeding $50,000. Thus, while rebuilding is an investment, it can be more cost-effective in the long run compared to buying new.

Economic Analysis

A cost-benefit analysis can help in deciding whether to rebuild or replace the engine. This involves considering not just the immediate costs, but also the long-term benefits in terms of engine performance and lifespan.

Breakdown of Rebuilding Costs

To give a clearer picture of what goes into the cost, here’s a detailed breakdown:

Major Components

- Cylinder Head: Cost of replacement or refurbishment.

- Crankshaft: Inspection and, if necessary, replacement costs.

- Pistons and Rings: Replacement costs and options.

Additional Parts and Services

- Filters, Seals, and Gaskets: The smaller, yet essential parts that add up.

- Oil Pump and Water Pump: Considerations for replacement and costs.

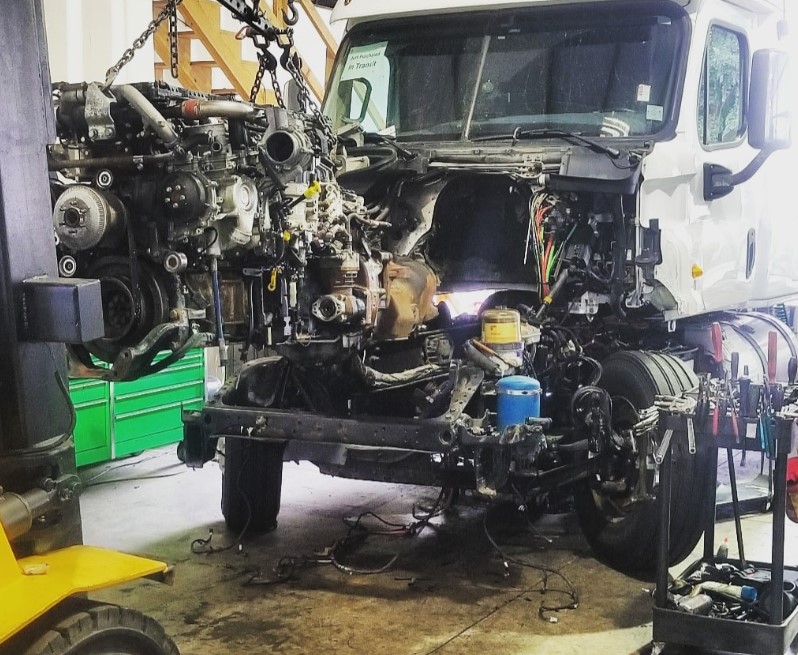

The Process of Rebuilding a DD15 Engine

Understanding the rebuilding process provides insights into the costs involved.

Step-by-Step Rebuilding Process

- Engine Disassembly: The meticulous process of dismantling the engine.

- Inspection: Evaluate each component to determine what needs repair or replacement.

Quality and Reliability

- Importance of using OEM parts.

- Ensuring the rebuild meets or exceeds original specifications.

Long-Term Benefits of a Quality Rebuild

While the initial cost might seem high, a quality rebuild offers long-term benefits.

Enhanced Engine Performance

- Improved fuel efficiency.

- Better reliability and reduced downtime.

Extended Engine Lifespan

- How a rebuild can extend the life of your DD15 engine.

- Comparison with the lifespan of a new engine.

Maintenance Tips Post-Rebuild

Post-rebuild maintenance is key to ensuring the longevity of the engine.

Regular Check-ups

- Importance of routine maintenance.

- Schedule and checklist for post-rebuild maintenance.

Best Practices

- Tips to maximize the performance and lifespan of the rebuilt engine.

Extended Warranties and Insurance Coverage

When rebuilding a DD15 engine, considering the availability of extended warranties and insurance coverage is crucial. These options can significantly influence the long-term value and protection of your investment.

The Role of Warranties in Cost Management

- Extended warranties can offer peace of mind by covering unforeseen issues post-rebuild.

- How to evaluate warranty options and what they cover in terms of parts and labor.

- Understanding how insurance can play a role in mitigating the financial impact of engine rebuilds.

- Tips for negotiating with insurance providers to get the best coverage for your rebuilt engine.

Technological Upgrades and Emission Standards

Modernizing a DD15 engine during the rebuild process can lead to better performance and compliance with emission standards.

Integrating Technological Advancements

- Opportunities to upgrade various engine components for enhanced efficiency and power.

- The impact of technology on the overall performance and longevity of the rebuilt engine.

Meeting Current Emission Standards

- How a rebuild can be an opportunity to ensure the engine meets or exceeds current environmental regulations.

- The importance of considering emission standards for compliance and environmental responsibility.

Impact on Vehicle Resale Value

The decision to rebuild a DD15 engine can also have implications on the vehicle’s resale value.

Enhancing Resale Value through Rebuilding

- How a professionally rebuilt engine can increase the market value of your truck.

- Strategies for documenting the rebuild process to maximize resale value.

Considerations for Future Sales

- The benefits of a rebuild in the context of future sales or trade-ins.

- Communicating the value of a rebuilt engine to potential buyers or dealers.

Alternatives to Complete Rebuilds

Not all situations require a full engine rebuild. Exploring alternatives can sometimes be more cost-effective.

Partial Rebuilds and Repairs

- Scenarios where a partial rebuild or specific repairs are sufficient.

- Cost comparisons between full and partial rebuilds.

Engine Replacement Options

- Situations where replacing the engine might be more viable than a rebuild.

- Cost and performance considerations when opting for an engine replacement.

User Experiences and Case Studies

Real-life examples and case studies can provide valuable insights into the rebuilding process.

Success Stories

- Testimonials from truck owners who have undergone the rebuilding process.

- Key lessons and takeaways from these real-world experiences.

Lessons from Challenging Scenarios

- Case studies of rebuilds that encountered unexpected challenges.

- How these challenges were overcome and what can be learned from them.

How Much Does It Cost To Rebuild A Freightliner Engine?

Rebuilding a Freightliner engine, particularly models like the DD15, involves various costs that can significantly vary based on multiple factors. The total cost typically includes expenses for parts, labor, and any additional upgrades or repairs needed.

- Parts: This cost encompasses all the components that need to be replaced during the rebuild. For a Freightliner engine, this could include items like pistons, rings, bearings, gaskets, and potentially larger components like the cylinder head or crankshaft. Depending on the quality and source of these parts, the cost can vary significantly.

- Labor: The complexity of Freightliner engines means that skilled labor is required for a rebuild. The labor cost will depend on the hourly rate of the technicians and the total hours required for the rebuild. This can vary based on the service center’s location and the specific requirements of the engine.

- Additional Costs: This may include any technological upgrades, such as improved fuel injectors or ECM programming, and any additional repairs that are identified during the rebuild process.

On average, the total cost of rebuilding a Freightliner engine like the DD15 can range from $20,000 to $30,000. However, this is a rough estimate, and the actual costs can be higher or lower based on the specific engine model, the extent of the rebuild, and regional variations in labor and parts costs.

What Are The Common Problems With DD15 Engine?

The DD15 engine, a popular model used in Freightliner trucks, is known for its reliability and performance. However, like any engine, it can have its share of problems. Understanding these common issues can help in maintaining and troubleshooting the engine effectively.

- EGR System Issues: The Exhaust Gas Recirculation (EGR) system in DD15 engines can sometimes face problems like clogging or malfunctioning. This can lead to reduced engine efficiency and increased fuel consumption.

- DPF Clogging: The Diesel Particulate Filter (DPF) can become clogged over time, especially if the truck is frequently used for short trips or at low speeds. A clogged DPF can cause reduced engine power and increased fuel consumption.

- Fuel System Problems: Issues with the fuel system, including the injectors and high-pressure fuel pump, are not uncommon. These can lead to a range of problems, including rough idling, loss of power, and increased fuel consumption.

- Turbocharger Failures: Turbocharger issues, often resulting from poor maintenance or oil contamination, can lead to significant power loss and decreased efficiency.

- Oil Leaks and Consumption: Some DD15 engines may experience oil leaks or higher than normal oil consumption, often due to issues with the oil pump or other components.

It’s important to note that regular maintenance and proper use can significantly reduce the likelihood of these problems. Additionally, addressing issues promptly when they arise can prevent more serious and costly repairs in the future.

Is It Expensive To Rebuild A Diesel Engine?

The cost of rebuilding a diesel engine can be relatively high, but it’s often more economical than purchasing a new engine. Several factors contribute to the overall expense of a diesel engine rebuild.

- Parts Costs: Diesel engine parts, such as pistons, rings, bearings, gaskets, and sometimes major components like the cylinder head or crankshaft, can be costly. The price of these parts varies depending on their quality, brand, and source.

- Labor Costs: Rebuilding a diesel engine is labor-intensive and requires skilled mechanics. The labor cost is determined by the hourly rate of the technicians and the total time taken for the rebuild. This can vary widely based on the workshop’s location and the specific model of the diesel engine.

- Additional Expenses: This may include costs for any upgrades, like better fuel injection systems or turbochargers, and additional repairs discovered during the rebuilding process.

On average, the cost to rebuild a diesel engine can range from $3,000 to $8,000 or more. This range is quite broad due to the variety of diesel engines and their applications. Heavy-duty diesel engines, like those in semi-trucks or commercial vehicles, can cost more to rebuild due to their size and complexity.

How Much Does It Cost To Replace A Semi-Truck Engine?

Replacing the engine of a semi-truck is a significant financial investment, primarily due to the high cost of the engines themselves and the labor involved in the installation.

- Engine Cost: The price of a new engine for a semi-truck varies greatly depending on the make and model. A new semi-truck engine can cost anywhere from $15,000 to $30,000 or more. Remanufactured engines might offer a cost-saving alternative, usually priced lower than brand-new engines.

- Labor Costs: Installing an engine in a semi-truck is a complex task requiring several hours of skilled labor. This cost will depend on the service center’s hourly rate and the time required for the installation.

- Additional Expenses: Apart from the engine and labor costs, there may be additional expenses for related components that need replacement during the engine installation, such as hoses, belts, and mounts.

Given these factors, the total cost to replace a semi-truck engine, including labor and any ancillary parts, can easily exceed $20,000. However, this investment can extend the life of the truck significantly, making it a viable option compared to purchasing a new vehicle.

Conclusion

Rebuilding a DD15 engine is a substantial but worthwhile investment. It offers a cost-effective alternative to buying new, with the added benefit of extending the lifespan and reliability of your engine. Understanding the factors that influence the cost and the benefits involved can help in making an informed decision that aligns with your long-term operational goals.

People Also Ask

Are there financing options available for DD15 engine rebuilds?

Many service centers offer financing options for engine rebuilds. Additionally, some lenders specialize in financing commercial vehicle repairs and upgrades. It’s worth exploring these options if upfront costs are a concern.

Does a DD15 engine rebuild include software updates?

Typically, a rebuild focuses on mechanical components. However, software updates for the ECM can be requested as part of the rebuild process. These updates can optimize engine performance and efficiency.

What maintenance is required after rebuilding a DD15 engine?

Post-rebuild maintenance includes regular oil changes, fuel filter replacements, coolant checks, and consistent monitoring of engine performance. Adhering to a strict maintenance schedule is crucial to prolong the life of the rebuilt engine.

Can a rebuilt DD15 engine meet current emission standards?

Yes, during the rebuild process, modifications and upgrades can be made to ensure the engine meets current emission standards. This is especially important for older engines to remain compliant with environmental regulations.

How long does it take to rebuild a DD15 engine?

The timeframe can vary based on the extent of the rebuild and the service center’s schedule. On average, a full rebuild can take between 2 to 4 weeks. It’s important to factor in this downtime in your planning.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.

![5.9 Cummins FCA Symptoms [Causes + Fixed]](https://www.turbochaos.com/wp-content/uploads/2023/12/5.9-Cummins-FCA-Symptoms-768x511.jpg)