How Many Crankshafts Are In A V8 Engine? Answered

In this comprehensive guide, we will delve into the heart of the V8 engine, focusing particularly on the question: “How Many Crankshafts Are In A V8 Engine?” This exploration will not only answer this specific query but also provide a deeper understanding of the V8 engine’s design and functionality.

In the world of automotive engineering, understanding the components of an engine is crucial for any enthusiast or professional. The V8 engine, renowned for its power and efficiency, stands as a prime example of mechanical ingenuity.

Key Takeaways

- The V8 engine contains one crankshaft.

- Crankshafts in V8 engines are designed for optimal balance and power distribution.

- The V8 engine’s layout contributes to its high performance and smooth operation.

- Understanding the role of the crankshaft helps in comprehending the engine’s overall functionality.

How Many Crankshafts Are In A V8 Engine?

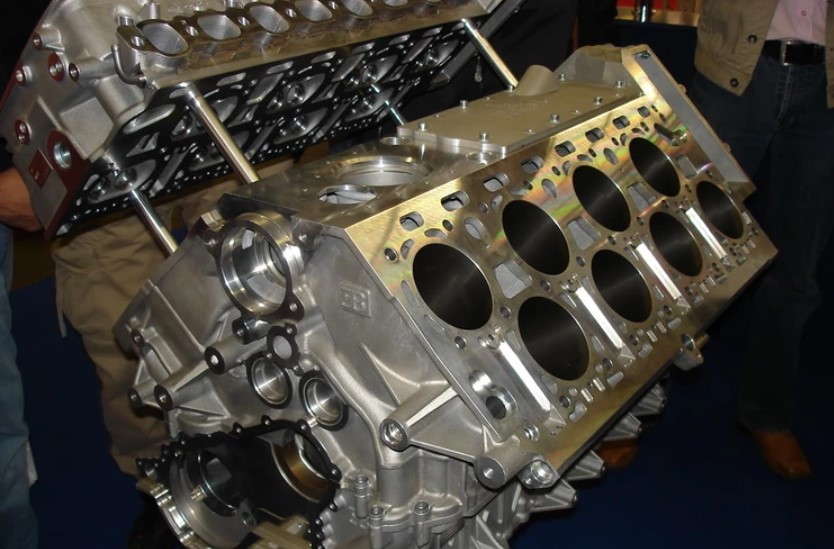

In any V8 engine, there is one crankshaft. This vital component serves as the backbone of the engine, converting the linear motion of the pistons into rotational motion, which is then transmitted to the wheels.

The design of the crankshaft in a V8 engine is critical for ensuring smooth operation and optimal power distribution across all eight cylinders.

Design and Functionality of the Crankshaft

The crankshaft in a V8 engine is intricately designed to maintain balance and reduce vibrations. Its configuration ensures that the pistons’ firing order optimizes power output while minimizing stress on the engine. The crankshaft’s durability is also paramount, as it must withstand high rotational speeds and significant forces during operation.

Understanding the V-Configuration

The V8 engine’s distinctive V-configuration plays a crucial role in its overall efficiency and performance. This layout allows for a compact design, reducing the engine’s overall size and weight.

The V-configuration also contributes to the engine’s balance, reducing vibrations and enhancing the vehicle’s smoothness and stability during operation.

Benefits of the V8 Layout

- Compact and efficient design.

- Enhanced power and torque output.

- Improved balance and reduced vibrations.

- High performance in a variety of vehicle applications.

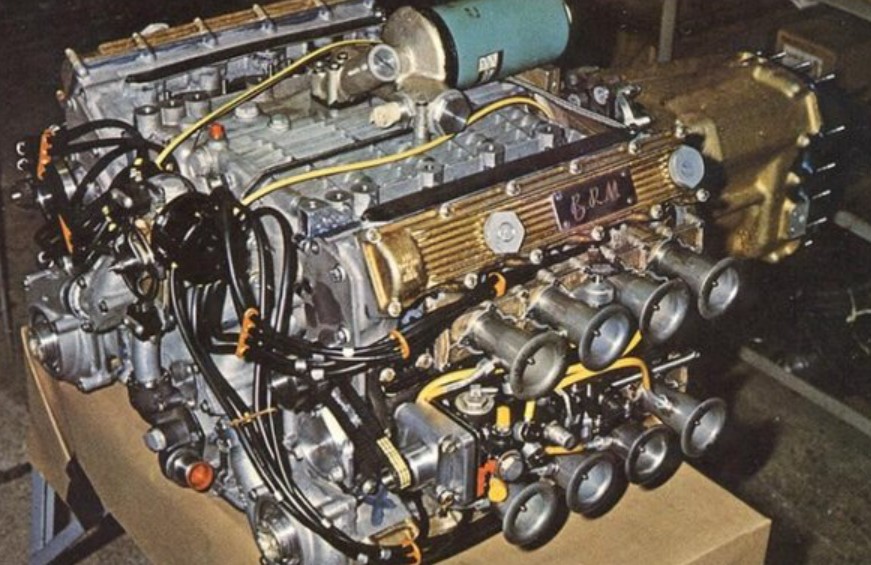

Components of the V8 Engine

The V8 engine comprises numerous components that work together to produce its remarkable power and efficiency. Key components include the pistons, connecting rods, camshaft, and, of course, the crankshaft. Each part plays a specific role in the engine’s operation, contributing to its overall functionality and performance.

Role of Key Components

- Pistons: Convert combustion energy into mechanical motion.

- Connecting Rods: Link pistons to the crankshaft.

- Camshaft: Controls the opening and closing of valves.

- Crankshaft: Transforms linear piston motion into rotational motion.

Performance and Efficiency in V8 Engines

The V8 engine is not just about power; it’s also about efficiency. Modern V8 engines are designed with advanced technologies, such as variable valve timing and direct fuel injection, to maximize fuel efficiency and reduce emissions. This combination of power and efficiency makes the V8 engine a versatile choice for various automotive applications.

Advancements in V8 Engine Technology

- Variable valve timing for optimized engine performance.

- Direct fuel injection for improved fuel efficiency.

- Turbocharging and supercharging for enhanced power output.

The V8 Engine in Different Vehicle Types

V8 engines are utilized in a wide range of vehicles, from high-performance sports cars to heavy-duty trucks. In each application, the engine is tuned and designed to meet the specific requirements of the vehicle, whether it’s for speed, power, or towing capacity.

V8 Engines in Various Applications

- Sports cars: Focus on high speed and acceleration.

- Luxury vehicles: Emphasize smooth and quiet operation.

- Trucks and SUVs: Prioritize torque and towing capacity.

Historical Evolution of V8 Engines

The history of V8 engines is a fascinating journey through automotive innovation. Initially developed in the early 20th century, V8 engines have undergone significant transformations.

The early versions were characterized by their simplicity and rudimentary design, which, while powerful, were not as efficient or reliable as modern iterations. Over the decades, advancements in technology and engineering have revolutionized V8 engines, making them more powerful, efficient, and reliable.

Milestones in V8 Development

- The introduction of overhead valves (OHV) enhanced power and efficiency.

- The adoption of fuel injection systems replaced carburetors for better fuel management.

- The development of aluminum engine blocks reduced weight and improved performance.

Maintenance and Care of V8 Engines

Maintaining a V8 engine requires a comprehensive understanding of its intricate systems. Regular maintenance is crucial for ensuring the longevity and optimal performance of the engine.

Key aspects of maintenance include regular oil changes, monitoring engine temperatures, and checking the integrity of the crankshaft and its associated components. Preventative maintenance not only prolongs the engine’s life but also ensures that it continues to operate at peak efficiency.

Key Maintenance Tips

- Regular oil changes to ensure proper lubrication and cooling.

- Routine inspection of belts, hoses, and gaskets to prevent leaks and failures.

- Monitoring engine performance and addressing issues promptly to avoid major repairs.

V8 Engines and Environmental Impact

In today’s environmentally conscious era, the V8 engine faces scrutiny regarding its impact on the environment. Despite their power and performance benefits, V8 engines are often associated with higher emissions and fuel consumption compared to smaller, more efficient engines.

However, manufacturers are continually innovating to reduce the environmental footprint of V8 engines, incorporating technologies like cylinder deactivation and hybridization to improve fuel efficiency and reduce emissions.

Innovations for Environmental Sustainability

- Cylinder deactivation technology to reduce fuel consumption during low-load conditions.

- Hybrid technologies that combine V8 power with electric motors for better efficiency.

- Development of cleaner and more efficient fuel systems to reduce emissions.

The Future of V8 Engines

As we look towards the future, the role of V8 engines in an increasingly eco-conscious and technologically advanced world is a topic of much debate.

While electric and hybrid technologies are becoming more prevalent, the V8 engine still holds a significant place, especially in applications where power and performance are paramount.

Manufacturers are focusing on balancing the need for power with environmental responsibilities, leading to innovative solutions that may redefine the V8 engine’s role in future automotive landscapes.

Prospects and Challenges

- Balancing performance with environmental responsibilities.

- Integrating advanced technologies to maintain relevance in a changing automotive market.

- Exploring alternative fuels and powertrains to complement traditional V8 engines.

How Many Pistons Does A V8 Engine Have?

A V8 engine, as the name suggests, has eight pistons. These pistons are arranged in two sets of four, forming a ‘V’ shape when viewed from the end of the engine. Each piston moves up and down within its own cylinder.

The pistons are connected to the crankshaft via connecting rods, and as the pistons move, they rotate the crankshaft, converting the linear motion into rotational motion, which ultimately powers the vehicle. This eight-piston configuration is key to the V8 engine’s high power output and smooth operation.

How Many Crankshafts Are There In A V6 Automobile Engine?

Like the V8 engine, a V6 engine typically contains only one crankshaft. The crankshaft in a V6 engine is designed to accommodate six pistons—three on each side of the V formation.

This single crankshaft is crucial for converting the linear motion of the pistons into the rotational motion that drives the vehicle. The design and placement of the crankshaft play an essential role in balancing the engine and ensuring efficient power transfer from the pistons to the drive shaft.

Conclusion

In conclusion, the V8 engine contains one crankshaft, a crucial component that plays a pivotal role in the engine’s functionality. This article has explored the intricacies of the V8 engine, shedding light on its components, design, and the vital role of the crankshaft.

Understanding these aspects highlights why the V8 engine continues to be a popular choice in the automotive world, revered for its power, efficiency, and versatility.

Frequently Asked Questions

What Is the Average Lifespan of a V8 Engine?

The lifespan of a V8 engine can vary greatly depending on several factors, including maintenance, usage, and the quality of its build. On average, a well-maintained V8 engine can last between 150,000 to 200,000 miles or more. Regular servicing, proper usage, and timely repairs can significantly extend the life of a V8 engine.

Can V8 Engines Be Fuel Efficient?

Contrary to popular belief, modern V8 engines can be relatively fuel-efficient. Advancements in technology such as variable valve timing, cylinder deactivation, and direct fuel injection have greatly improved the fuel economy of V8 engines. These technologies allow the engine to adjust its performance according to driving conditions, thus optimizing fuel usage.

Are V8 Engines Better Than V6 Engines?

Whether a V8 engine is “better” than a V6 depends on the specific needs and preferences of the user. V8 engines generally provide more power and torque, making them ideal for high-performance vehicles and heavy-duty applications. V6 engines, on the other hand, are often more fuel-efficient and produce less emissions, which might be preferable for everyday use and for those prioritizing environmental considerations.

How Does Cylinder Deactivation Work in V8 Engines?

Cylinder deactivation in V8 engines allows the engine to shut off a portion of its cylinders under certain conditions, such as cruising or light load, to save fuel. This system can deactivate half of the engine’s cylinders, effectively turning a V8 into a four-cylinder engine. When more power is needed, the system reactivates the deactivated cylinders. This technology improves fuel efficiency without sacrificing performance.

What Makes V8 Engines Popular in Sports Cars?

V8 engines are popular in sports cars due to their high power output and torque, which are essential for fast acceleration and high-speed performance. The V8’s design allows for smooth power delivery and a distinctive engine sound, both highly valued in sports cars. Additionally, the V8’s balance and low vibration contribute to a more stable and enjoyable driving experience.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.