How Long Does It Take To Build An Engine? Answered

Building an engine, whether for a car, a motorcycle, or industrial machinery, is a complex and intricate process. This article will explain How Long Does It Take To Build An Engine? depends on various factors. These include the type of engine, the builder’s expertise, the tools available, and the specific performance requirements. The process can range from a few days to several weeks or even months.

Key Takeaways

- Understanding the complexity and time needed to build an engine.

- Factors that influence the construction time of an engine.

- Comparison between professional and amateur engine building.

- Key stages in engine assembly and testing.

How Long Does It Take To Build An Engine?

Building a standard automotive engine can take anywhere from 20 to 40 hours for a professional mechanic. For an amateur or enthusiast, the process might take significantly longer, possibly several weeks, due to less frequent work periods and a learning curve.

Factors Influencing Build Time

- Engine Complexity: V8 engines are more complex than inline-four engines, requiring more time.

- Skill Level of the Builder: Professionals work faster due to experience and skill.

- Tools and Equipment: High-quality tools can significantly reduce build time.

- Engine Condition: Rebuilding an old engine can take longer due to cleaning and repairing parts.

Stages of Engine Building

- Planning and Design: Assessing requirements and sourcing parts.

- Assembly: Physical construction of the engine.

- Testing and Troubleshooting: Ensuring everything functions correctly.

Professional vs. Amateur Engine Building

Professional Approach

Professionals have access to advanced tools and a wealth of experience, which streamlines the building process. They are adept at troubleshooting and often have a network of suppliers for quality parts.

Amateur Approach

Amateurs often take a DIY approach, learning as they go. This can extend the build time but offers a deeper understanding of the mechanics. It can be a more cost-effective but time-consuming process.

Key Stages in Engine Assembly

Initial Preparation

- Cleaning and Inspection: Essential for a reliable build.

- Organizing Components: Ensures efficiency and reduces errors.

Assembly Process

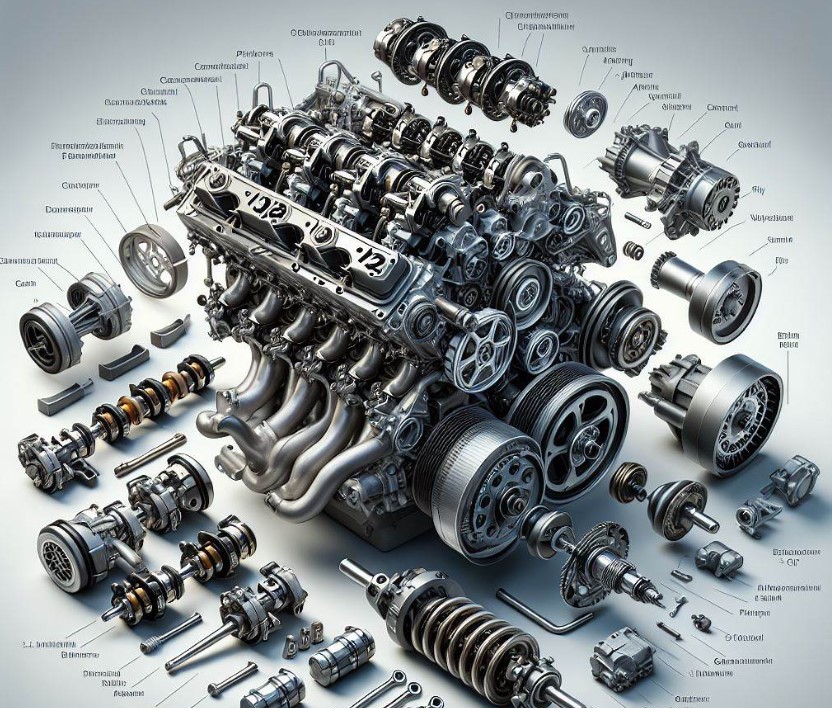

- Crankshaft and Pistons Installation: A critical stage that sets the foundation for the engine.

- Cylinder Head Assembly: Involves precision and attention to detail.

Testing and Quality Assurance

Testing Phase

Testing is crucial to validate the performance and safety of the engine. It often includes bench tests and, in some cases, actual road tests.

Quality Assurance

Professional builders follow stringent quality control protocols. This ensures reliability and performance standards are met.

How Long Does Getting A New Engine Take?

The time it takes to get a new engine can vary based on several factors, including the type of engine, availability, and the supplier’s location. Generally, if an engine is readily available and in stock, it might take a few days to a week for delivery. However, for custom or rare engines, the wait time can extend to several weeks or even months.

The ordering process itself is usually quick, but factors like shipping logistics, engine build time (if it’s being custom-made), and the supplier’s backlog can extend the timeline. For instance, high-performance or specialty engines that are not mass-produced may require additional build and testing time at the manufacturer before they are shipped.

How Hard Is It To Build An Engine?

Building an engine is a complex and challenging task that requires mechanical expertise, precision, and patience. The difficulty level depends on the type of engine and the builder’s experience.

For a professional mechanic, building a standard engine is a routine task, although still complex and time-consuming. It involves understanding intricate details like torque specifications, timing alignments, and the fitting of various components.

For amateurs or enthusiasts, the process can be quite daunting. It requires not only a fundamental understanding of how engines work but also a detailed knowledge of the specific engine being built.

Mistakes in the process can lead to engine failure, so meticulous attention to detail is essential. The availability of proper tools and a suitable workspace also plays a significant role in the ease of the build.

How Long Does It Take A Dealership To Rebuild An Engine?

The time it takes for a dealership to rebuild an engine can vary widely, typically ranging from a few days to several weeks. This timeframe depends on factors like the extent of the rebuild required, the availability of parts, and the dealership’s workload.

A basic rebuild, where major components like the crankshaft and pistons are in good condition, might be quicker. However, a comprehensive rebuild, involving extensive repairs or replacement of several parts, will take longer. Additionally, if parts need to be ordered, especially for older or less common engines, this can add to the timeline.

Dealerships with a dedicated engine rebuilding section may complete the work faster than smaller shops due to more specialized equipment and expertise. It’s also important to note that quality and thoroughness should take precedence over speed to ensure a reliable and long-lasting engine rebuild.

Conclusion

In conclusion, building an engine is a task that varies greatly in duration. It can take a professional approximately 20 to 40 hours, while an amateur may take several weeks.

The complexity of the engine, the builder’s skill, and the quality of tools and parts play significant roles in determining the build time. This craft requires patience, precision, and a deep understanding of mechanics, whether undertaken by a professional or an enthusiast.

Frequently Asked Questions

What is the importance of testing in the engine building process?

Testing is crucial to ensure the engine functions correctly and safely. It involves checking for leaks, verifying the correct operation of all components, and ensuring the engine meets performance standards. This phase can identify any issues that need addressing before the engine is considered complete and ready for use.

Can the engine building process be expedited?

While certain steps can be optimized for efficiency, rushing the engine-building process is generally not advisable. Precision and attention to detail are critical for a reliable build. However, having a well-organized workspace, using quality tools, and following a systematic approach can make the process more efficient.

How does the experience level of the builder affect the build time?

Experience significantly impacts build time. Professional mechanics with experience can build engines more quickly and efficiently, leveraging their skills and knowledge to avoid common pitfalls. Amateur builders may take longer due to a learning curve and a more cautious approach to assembly.

What are the common mistakes to avoid when building an engine?

Common mistakes include improper torque application, incorrect timing settings, not following the engine’s specific assembly manual, and using incompatible or substandard parts. These errors can lead to engine failure and significantly increase build time due to the need for rework.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.