How Does A Kohler Engine Charge The Battery? Explained

Understanding How Does A Kohler Engine Charge The Battery? is crucial for anyone using Kohler-powered equipment. These engines, renowned for their reliability and efficiency, have a charging system designed to keep the battery fully charged while the engine runs.

This system ensures seamless operation of your equipment, whether it’s a lawn mower, generator, or other machinery. Let’s delve into the intricacies of this process and discover the engineering behind Kohler’s charging system.

Key Takeaways

- Kohler engines charge the battery using an alternator.

- The alternator is part of the engine’s electrical system.

- Voltage regulation is key for safe and efficient charging.

- Regular maintenance ensures the charging system’s longevity.

- Understanding this process can help in troubleshooting and maintenance.

How Does A Kohler Engine Charge The Battery?

A Kohler engine charges the battery by converting mechanical energy into electrical energy. This conversion is done by an alternator, which is an integral part of the engine’s electrical system.

When the engine runs, the alternator spins, generating AC (Alternating Current) electricity. This electricity is then converted into DC (Direct Current) to charge the battery and power the engine’s electrical components.

Alternator Function and Mechanism

The alternator, essentially an electric generator, is key to the process of charging. It contains a rotor, stator, and diode assembly. As the engine runs, the crankshaft drives the alternator’s rotor, creating a magnetic field.

This field interacts with the stator windings, generating AC electricity. The diode assembly then rectifies this AC into DC electricity suitable for battery charging.

Voltage Regulation and Battery Charging

Proper voltage regulation is crucial in this system. Kohler engines use a voltage regulator to ensure that the battery receives a consistent and safe charge.

This regulator maintains the output voltage of the alternator within a specific range, usually around 12 to 14 volts, which is ideal for charging the battery without causing damage or reducing its lifespan.

Electrical System Components and Functions

The Kohler engine’s charging system comprises several components, each playing a vital role. Understanding these components helps in troubleshooting and maintenance.

Battery and Its Role

The battery stores electrical energy and provides power to start the engine and run electrical accessories. It’s a rechargeable unit that receives charge from the alternator.

Wiring Harness and Connections

A wiring harness connects the alternator, voltage regulator, battery, and other electrical components. Proper connections and insulation are crucial for efficient and safe operation.

Maintenance and Troubleshooting of the Charging System

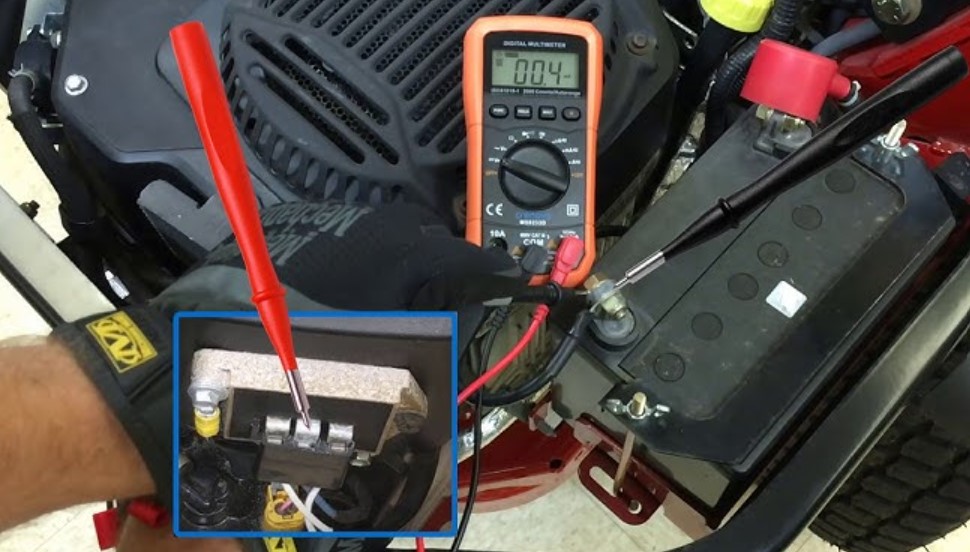

Regular maintenance ensures the longevity and efficiency of the charging system. This includes checking connections, inspecting the alternator and voltage regulator, and testing the battery.

Routine Maintenance Tips

- Inspecting the Alternator: Check for wear, damage, and proper connections.

- Battery Care: Regularly check battery terminals for corrosion and ensure it’s adequately charged.

- Voltage Regulator Check: Ensure it’s functioning correctly to prevent overcharging or undercharging.

Common Troubleshooting Scenarios

- Battery Not Charging: This could indicate a faulty alternator or regulator.

- Engine Starting Issues: Often related to a weak or dead battery.

- Electrical Component Failure: This may suggest problems in the wiring harness or connections.

Advanced Charging System Features in Modern Kohler Engines

Kohler continues to innovate, introducing advanced features in their charging systems to enhance efficiency and reliability.

Smart Charging Technology

Newer Kohler engines may incorporate smart charging technology. This adapts the charging rate based on battery condition and load, optimizing performance and extending battery life.

Enhanced Voltage Regulation

Advanced voltage regulators in newer models provide more precise control over the charging process, contributing to battery longevity and consistent engine performance.

The Importance of a Properly Functioning Charging System

A well-functioning charging system is crucial for the reliability and efficiency of Kohler-powered equipment. It ensures that the battery is consistently charged, preventing issues like power loss or engine failure.

Implications of a Malfunctioning Charging System

- Reduced Battery Life: An improperly charged battery can have a shortened lifespan.

- Operational Inefficiency: A failing charging system can lead to power loss or engine stoppage.

- Increased Maintenance Costs: Neglecting the charging system can lead to more significant, costly repairs.

Optimizing Charging System Performance

Maximizing the performance of a Kohler engine’s charging system is crucial for ensuring longevity and reliability. This involves not only regular maintenance but also understanding and addressing common issues that may arise during its operation.

Strategies for Optimal Performance

- Regular Inspections: Conduct thorough inspections of the charging system components, including the alternator, voltage regulator, and battery, to identify any wear or potential issues early.

- Balanced Electrical Load: Ensure that the electrical load on the engine is balanced. Overloading the system with too many electrical accessories can strain the charging system, leading to inefficiencies.

Upgrading Components for Enhanced Efficiency

Upgrading certain components of the charging system can significantly boost its efficiency and reliability. For instance, installing a high-performance alternator or an advanced voltage regulator can improve the system’s ability to charge the battery effectively, especially in demanding conditions.

Dealing with Environmental Impacts

Environmental factors can significantly impact the performance of a Kohler engine’s charging system. Extreme temperatures, humidity, and dirt accumulation are common issues that can affect its efficiency.

Impact of Temperature Extremes

- Cold Weather: In colder climates, the battery’s efficiency can decrease, requiring the charging system to work harder.

- Hot Weather: High temperatures can lead to increased wear and tear on the charging system components, especially the battery.

Protective Measures Against Harsh Conditions

Implementing protective measures can mitigate the impact of harsh environmental conditions on the charging system.

- Insulation and Ventilation: Proper insulation and ventilation can help maintain optimal operating temperatures.

- Regular Cleaning: Keeping the engine and its components clean from dirt and debris ensures better performance and reduces the risk of overheating.

Innovations in Kohler Charging Systems

Kohler’s continuous innovation in engine technology includes advancements in their charging systems. These innovations aim to provide better performance, reliability, and environmental friendliness.

Introduction of Efficient Alternators

Kohler has introduced more efficient alternators in their newer models. These alternators are designed to generate more power at lower engine speeds, ensuring the battery is charged effectively even under light engine loads.

Eco-Friendly Charging Solutions

Kohler is also focusing on eco-friendly solutions, like charging systems that reduce energy waste and improve the overall efficiency of the engine. This not only benefits the environment but also enhances the engine’s performance and longevity.

Addressing Common Misconceptions

There are several misconceptions about charging systems in Kohler engines that need clarification. Understanding these can help in better maintenance and operation of the equipment.

Myth vs. Reality in Charging Systems

- Myth: A larger battery will improve the charging system’s efficiency.

- Reality: The size of the battery does not necessarily impact the efficiency of the charging system; it’s more about the compatibility and condition of the battery.

Clarifying the Role of the Voltage Regulator

- Misconception: The voltage regulator can repair a failing battery.

- Truth: The voltage regulator’s role is to control the voltage output of the alternator, not to repair or rejuvenate batteries.

Future Trends in Kohler Charging Technologies

Looking ahead, Kohler is poised to introduce more advanced technologies in their engine charging systems. These advancements are likely to focus on improving efficiency, reducing environmental impact, and enhancing user experience.

Integration with Smart Technologies

The integration of smart technology in charging systems is a potential future development. This could include systems that can self-diagnose issues and adjust charging parameters based on real-time data.

Sustainable Charging Solutions

Kohler is likely to continue its focus on sustainability, developing charging systems that are more energy-efficient and less impactful on the environment. This could involve the use of renewable energy sources or more efficient electrical components.

What Charges The Battery On A Kohler Motor?

The battery on a Kohler motor is charged by an alternator, also known as a charging coil. The alternator functions as the power generator for the system. It is driven by the motor’s crankshaft, which turns the rotor inside the alternator.

This motion generates alternating current (AC) electricity through electromagnetic induction. The generated AC is then converted to direct current (DC) by a diode rectifier, as DC is required to charge the battery and power other electrical components in the engine system.

The charging system also includes a voltage regulator. This component is crucial as it ensures the voltage delivered to the battery is consistent and safe.

It protects the battery from overcharging, which can significantly shorten its lifespan. The regulator keeps the output voltage of the alternator within a specified range, typically around 12-14 volts, ideal for charging the battery without causing damage.

This information about the charging system in a Kohler motor can be verified from Kohler’s official documentation and user manuals, which provide detailed insights into their engine systems and components.

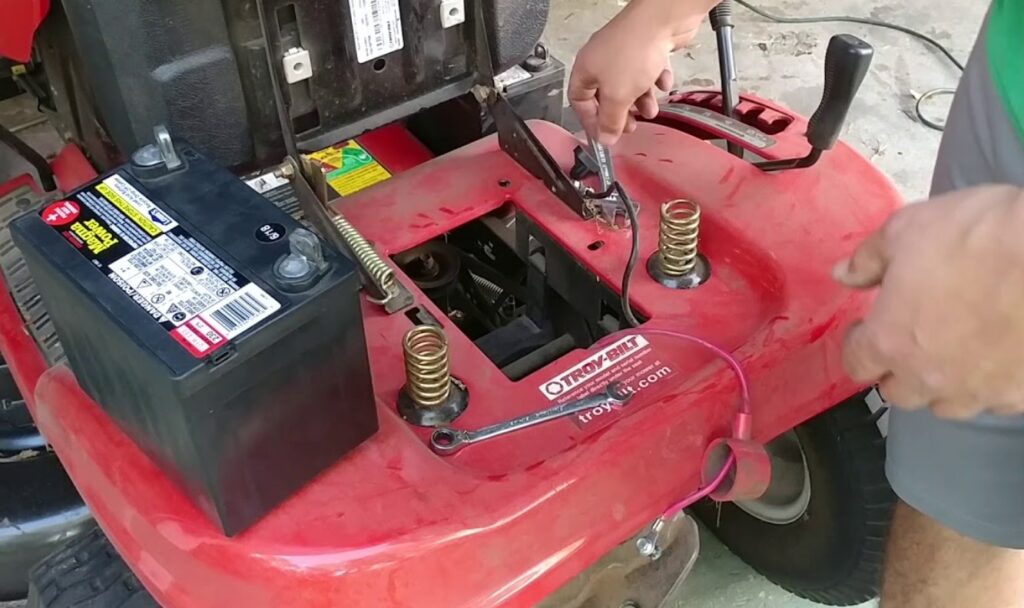

How Does A Riding Lawn Mower Charge Its Battery?

The charging mechanism in a riding lawn mower, particularly those powered by Kohler motors, operates similarly to other small engine equipment. When the engine is running, the alternator or charging coil generates electrical power.

This alternator, driven by the engine’s movement, produces alternating current (AC). The current is then rectified into direct current (DC) using a diode or a rectifier bridge, making it suitable for charging the battery.

In addition to the alternator and rectifier, a voltage regulator plays a pivotal role in this process. It maintains the voltage at an optimal level for the battery, preventing overcharging and ensuring that the battery receives a steady and safe charge.

This setup is designed to keep the battery charged as long as the engine is running, thus providing enough power for the mower’s next start-up and for running any electrical accessories.

The specifics of this charging mechanism can vary slightly based on the model and make of the riding lawn mower, but the fundamental process remains consistent across most models.

This information about riding lawn mower charging systems can be validated through user manuals and technical guides provided by various lawn mower manufacturers, including those that use Kohler engines.

Do Kohler Motors Have An Alternator?

Kohler motors, particularly those used in lawn mowers and other small outdoor power equipment, do indeed have an alternator. The alternator in Kohler motors is a key component of the engine’s electrical system.

It serves the primary function of generating electrical power when the engine is running. This power is used to charge the battery and to supply electricity to other electrical components of the machine.

The alternator in a Kohler motor typically operates as a small magnetic coil. When the engine runs, the movement of the crankshaft spins the rotor located within the alternator.

This spinning action creates alternating current (AC) electricity through the principles of electromagnetic induction. The electricity generated is then converted into direct current (DC) via a rectifier, as DC is necessary for charging the battery and for powering the engine’s electrical system.

Additionally, the system includes a voltage regulator to ensure that the electricity produced by the alternator is delivered to the battery at a consistent and safe voltage. This regulation is crucial for preventing battery overcharge and ensuring the longevity and efficiency of the battery and electrical system.

This information about Kohler motors and their alternators can be corroborated with technical specifications and manuals provided by Kohler for their range of engines.

How Do Small Engines Charge The Battery?

In small engines, such as those found in lawn mowers, generators, and similar equipment, the battery is charged by an integral charging system. This system typically includes an alternator (or a charging coil), a rectifier, and a voltage regulator.

The alternator generates electrical power when the engine is running. It usually consists of a magnet on the flywheel and a stationary coil of wire.

As the flywheel rotates with the engine’s crankshaft, it induces an alternating current (AC) in the coil. This AC is then converted to direct current (DC) by the rectifier. The rectified current is suitable for charging the battery and powering the engine’s electrical components.

The voltage regulator plays a vital role in this process. It ensures that the voltage output from the alternator is neither too high nor too low.

A consistent voltage level is crucial for safe and effective battery charging. Without a regulator, the varying engine speeds could cause fluctuating voltages, potentially leading to battery overcharging or undercharging.

The charging system in small engines is designed to be efficient and self-contained, requiring minimal maintenance under normal operating conditions. These details about small engine charging systems can be found in various engine manufacturers’ service manuals and technical documentation.

Conclusion

Understanding how a Kohler engine charges the battery is vital for anyone operating Kohler-powered machinery. A well-maintained charging system ensures that your equipment runs smoothly and efficiently, saving time and money in the long run.

Regular checks and maintenance of the alternator, voltage regulator, and battery will keep your Kohler engine’s charging system in top condition, providing reliability and peace of mind.

Frequently Asked Questions

What is the role of the alternator in a Kohler engine?

The alternator in a Kohler engine generates electrical power as the engine runs. It converts mechanical energy into electrical energy, providing the necessary current to charge the battery and power the engine’s electrical systems.

How does a voltage regulator work in a Kohler engine?

The voltage regulator in a Kohler engine controls the output voltage from the alternator, ensuring it remains within a safe range for the battery and electrical components. It prevents overcharging or undercharging, which can harm the battery and affect engine performance.

Can I upgrade the alternator in my Kohler engine for better performance?

Yes, upgrading the alternator can enhance the charging system’s efficiency. A high-performance alternator may generate more power at lower engine speeds, ensuring better battery charging, especially under heavy electrical loads.

What maintenance is required for the charging system of a Kohler engine?

Regular maintenance includes inspecting the alternator and voltage regulator for wear or damage, checking and cleaning battery terminals, ensuring all electrical connections are secure, and keeping the battery properly charged.

How do environmental factors like temperature affect the Kohler engine’s charging system?

Extreme temperatures can impact battery efficiency and the overall performance of the charging system. Cold weather can reduce battery capacity, while hot weather can increase wear on the system’s components. Proper insulation and ventilation can mitigate these effects.

Welcome to the exhilarating world of Matt Rex, a professional car racer turned renowned vehicle enthusiast. Immerse yourself in his captivating blog as he shares heart-pounding adventures, expert reviews, and valuable insights on cars, trucks, jets, and more. Fuel your passion for speed and discover the beauty of vehicles through Matt’s engaging stories and meticulous expertise. Join the ever-growing community of enthusiasts who find inspiration and expert advice in Matt Rex’s blog—a digital hub where the thrill of speed meets the pursuit of knowledge.