Positive Temperature Coefficient (PTC) Heater (Explained)

This article will explain Positive Temperature Coefficient (PTC) Heater. When you most needed your film heater, did it ever cease working? Have you ever heard of hot spots or overheating vehicle seats? We have relied on fixed-resistance heaters for most of our demands for many years.

Safety is still a major concern when a single-point sensor “assumes” the heater’s full temperature. We use traditional heaters broadly throughout industries despite the numerous problems that have afflicted them. However, Boyd has the solution to all these problems: A Positive Temperature Coefficient (PTC) Heater, a technique that prioritizes safety.

Positive Temperature Coefficient (PTC) Heater

PTC heaters, or positive temperature coefficient heaters, are self-regulating heaters that operate open-loop without outside diagnostic controls. PTC heaters use conductive inks printed on weak, flexible polymer-based substrates to generate heat instead of the wires and coils used in conventional fixed-resistance heaters.

They excel at efficiency and dependability, making them the best choice for products that need to be heated more evenly, quickly, and safely. The PTC heater doesn’t require any additional feedback controls because of the characteristics of the material, which enable it to function as its sensor. As a result, the heater automatically reduces the possibility of overheating.

PTC heaters use materials with positive temperature coefficients, which change their resistance positively as the temperature rises. The material’s electrical resistance also rises with temperature, which restricts the current flow. When the material is cold, the current can flow freely, but as the threshold temperature rises, the material inhibits the current flow.

PTC heaters initially consume all their electricity to heat quickly and attain the ideal temperature. Power usage decreases as heat production rises. This dynamic heating technology not only works well, but it also saves time and energy.

PTC heaters can be made to function at temperatures ranging from -40°C to 70°C (from -40°F to 158°F). The design phase allows for customization of the threshold temperature. Creating heaters with different temperature zones is possible, and minor adjustments can modify the watt density.

Conductive inks are changing printed electronics by combining performance and usefulness in parts like PTC heaters. PTC heaters provide designers with the opportunity to create complex heating patterns.

They enable high-volume production and are also cost-effective and abrasion-resistant. A Positive Temperature Coefficient heater is created by screen printing carbon conductive inks onto substrates made of polymers. Although polyester is the most common substrate material, other ones can also be employed.

The PTC conductive inks can withstand numerous heating and cooling cycles. The printed circuits are sealed with an adhesive laminate to stop mechanical abrasion and moisture intrusion. Constructions that are sealed can survive harsh exterior elements and the rigors of heavy use.

What Is A PTC Heater?

A PTC heater is an electric appliance that produces heat using the Positive Temperature Coefficient (PTC) technology. PTC heaters use conductors made of materials with variable resistance to generate heat, unlike conventional heating elements, which rely on low fixed-resistance coils.

These conductors produce resistance, heat up, and release heat into the environment as electricity flows through them. The “PTC effect” describes how they heat up more and more when more electricity is passed through them, but they never get hot enough to burn or catch fire. They provide a very similar function to radiators but are considerably more effective.

The Advantages Of A PTC Heater

You might be asking what the advantages of a PTC heater are over conventional heaters if you are still familiar with the intricacies of heating systems, as many people aren’t. PTC heaters are significantly more energy efficient than conventional types since they utilize less power.

As a result, you can reduce the amount you pay monthly for utilities without compromising the efficiency of your home’s heating system. Additionally, PTC heaters are much safer for houses with young children or pets because they don’t have any exposed wiring or open flames like some traditional models do.

Finally, compared to other heating systems, these devices require relatively minimal maintenance because they don’t rely on any moving components or filters to function. The benefits follow suit and are clear:

- The likelihood of overheating is greatly decreased because the temperature automatically regulates itself at the optimum maximum. This makes the heater more secure.

- Before self-regulation takes effect, low resistance at low temperatures produces a quick rise in temperature and high resistance at high temperatures—consequently, quick response and automated peak level.

- To prevent hot spots and apply uniform and flexible heating beneath various shapes and materials, the substrate design and the printed areas can be modified to the object’s contour.

- The heaters are extremely lightweight since they are printed on tiny foils. Additionally, this printing method is more environmentally friendly than most others because it uses an additive process rather than an etching one.

- By utilizing the appropriate inks, the desired maximum temperature can be established. Today, we provide products that keep temperatures of 40, 60, 90, or 105 °C constant.

What Is It Like Compared To Conventional Heaters?

It is simple to understand why so many people favor utilizing PTC heaters in their homes side-by-side with conventional heating elements. Traditional heating elements create more intense heat, but they also need more energy to operate, and because the parts wear out over time, maintenance costs can mount up quickly.

On the other hand, PTC heaters produce consistent low-level warmth without incurring additional maintenance or upkeep costs. PTC heaters allow you to take special design considerations because they are more portable and lightweight than conventional elements.

What Is The Function Of A Traditional Heating Element?

Most conventional space heaters convert electrical currents into thermal energy using conductive wires or coils. The most prevalent kind of wire used today is nichrome. Nichrome has a positive temperature coefficient, just like other conductive wires.

However, unlike PTC components, the current is not sufficiently reduced at high temperatures to prevent the wire from becoming excessively hot.

These heaters feature electrical safety switches to prevent overheating and fire risk. The heating element’s electricity is turned off if internal sensors detect an excessive increase in temperature.

This system is extremely safe if these sensors and the related switches function properly. However, nothing would prevent the device from overheating if a sensor or switch malfunctioned.

Traditional electric heaters take a long time to heat up, using more and more energy as time passes to raise the element’s temperature. The current is shut off or restricted, and the element starts to cool when the electrical sensors detect that the maximum temperature or fixed temperature has been reached. The element will start to reheat whenever the temperature drops below the threshold.

Because of this, PTC heaters are much more effective than conventional heaters.

How Does A PTC Heating Element Work?

PTC heating components convert thermal energy from the electrical current as well. However, they have a strong enough positive temperature coefficient that is self-limiting. This means that as an element warms up, it loses its ability to conduct current, which lowers the temperature.

Different types of materials can be used to create PTC heating components. They are typically flexible fabrics with conductive inks printed for many purposes. PTC elements in space heaters often come in ceramic discs made of high barium titanate.

Depending on the application, these discs can be produced to operate at varying maximum temperatures. The ceramic used in space heaters intended for residential use is normally produced to a maximum temperature of about 500 degrees.

PTC heating elements don’t need additional sensors or switches because they are self-limiting. The heating element itself instead controls the amount of heat produced. The current flowing through the element slows down proportionately to its increasing temperature.

Put another way, PTC heaters enable current to flow when the upper and ambient temperatures are low and limit it when they are high. A PTC element will keep a constant temperature once the maximum temperature has been reached while utilizing little electricity until the surrounding temperature changes.

The element will completely stop moving current if it malfunctions or sustains some harm. This implies that even a PTC heating element that isn’t working properly can’t overheat. A PTC heater will immediately consume its power when it is turned on during normal use.

Power consumption will drop as an element’s temperature rises, reaching a low steady state as it hits its maximum temperature. This leads to high initial power consumption but low overall power consumption. In addition to being more energy-efficient as a result, PTC heaters also generate heat more quickly than conventional electrical heating components.

Types Of PTC Heaters

There are several different types of PTC heating components. They have countless applications because they are open-loop, do not need external control, and can be used with flexible textiles.

Your car’s seat and steering wheel heaters are constructed of PTC conductive ink. The same may be said about your puffer jacket’s fancy heated lining. PTC heating elements are frequently employed in the medical sector to keep patients at ease during surgery and recovery. PTC heating elements for space heaters are primarily available in two varieties: aluminum fin and honeycomb.

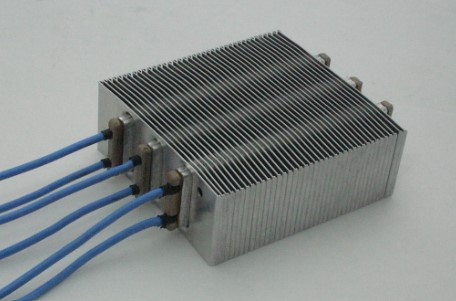

Aluminum Fin Heaters

Aluminum fin heaters help to distribute heat throughout the space by combining a PTC ceramic block with conductive aluminum fins.

The ceramic heats up as a result of current flowing through it. After then, the extremely conductive aluminum fins receive the heat. These fins can be used to push air over them and into the room using an internal fan, or they can be used to transfer heat to the air convectively.

Like all PTC heating elements, these types have self-limiting capabilities and don’t need any electrical sensors to prevent overheating. They can be made with various temperature maximums for usage with target temperatures and numerous heat settings. Alternatives include writing a maximum temperature point onto the ceramic block and using varied fan speeds to achieve various heat outputs.

Honeycomb Heaters

PTC ceramic discs with countless tiny holes drilled through them make up the honeycomb heating components. Air may flow straight through the heating elements thanks to these perforations. When combined with an internal fan, these devices are very efficient at transferring hot air from the heater into the room.

Additionally self-limiting and incredibly secure, these PTC heaters. They can be produced to have a variety of temperature maximums, just as aluminum fin heaters allow for various heat settings and goal temperature settings. Or they can use different fan settings to circulate heat into the space at various rates.

Conclusion

A Positive Temperature Coefficient (PTC) Heater, or semiconductor, is an electrical heating element made of ceramic with temperature-dependent resistance. Thanks to its positive temperature coefficient, electrical current flows more freely at low temperatures than at high temperatures.

The PTC’s natural resistance grows as the temperature rises, and its current conductivity and power output fall simultaneously until an equilibrium is established and the current can hardly flow any longer. The so-called PTC impact is that.

Frequently Asked Questions

What is the PTC heater’s temperature?

Internal temperatures of conventional heaters can reach 900°F (482°C) or more. In contrast, PTC heaters typically operate at 518°F (270°C). As one may anticipate, safety will always rise as operating temperatures decrease.

What is the PTC heating platform’s temperature control?

When operated from a constant voltage source, the resistance rises as the element warms up, often sharply at the desired temperature, reducing the current and hence the heat produced. It automatically adjusts itself to the temperature that serves as its transition point.

What distinguishes a positive temperature coefficient from a negative one?

A component with a negative temperature coefficient becomes less resistive as it gets hotter. A component with a positive temperature coefficient becomes more resistive as it gets hotter. In a resistance versus temperature graph, it is simple to see the polarity of the temperature coefficient.

What is the PTC heater’s formula?

The temperature difference dT and the heat-dissipating surface A determine how powerful a PTC heater is. The equation P = * A + (dT), where is the heat transfer coefficient, describes this relationship.

Matt Rex brings 12 years of specialized automotive expertise, holding a professional degree in Automotive Engineering Technology. As the founder of Turbochaos, he delivers comprehensive diagnostic services, performance optimization, and fleet maintenance solutions, backed by advanced certifications in hybrid/electric systems and ADAS technology. Its innovative methodologies have earned industry recognition while maintaining a 98% customer satisfaction rate.