What Should A Map Sensor Read Key On Engine Off? Answered

Are you looking for What Should A Map Sensor Read Key On Engine Off? This question often perplexes vehicle owners and mechanics alike. The Manifold Absolute Pressure (MAP) sensor is a crucial component in a vehicle’s engine management system.

It provides vital data for the engine control unit (ECU) to balance and deliver the correct air-fuel mixture for efficient combustion. This article delves into the specifics of MAP sensor readings, particularly when the key is on but the engine is off.

Key Takeaways

- The MAP sensor reading with the key on and engine off typically ranges from 4.6 to 4.8 volts.

- This reading is essential for diagnosing potential issues with the engine or the sensor itself.

- Variations in readings can indicate various engine problems, necessitating immediate attention.

What Should A Map Sensor Read Key On Engine Off?

When the key is on and the engine is off, a MAP (Manifold Absolute Pressure) sensor should typically read close to atmospheric pressure, which is usually around 4.6 to 4.8 volts. This corresponds to approximately 100 kPa (kilopascals) or 29.92 inHg (inches of mercury) at sea level.

Understanding MAP Sensors and Their Importance

How MAP Sensors Work?

The MAP sensor functions by detecting the air pressure within the intake manifold. This pressure data is crucial as it indicates the engine’s load to the ECU. With the key on and the engine off, the sensor measures the atmospheric pressure, which is critical for the ECU to set the baseline for operation.

The Role of MAP Sensors in Engine Management

MAP sensors play a pivotal role in optimizing engine performance. They help in adjusting the fuel injection and ignition timing based on the engine’s load. This adjustment is vital for achieving maximum fuel efficiency and reducing emissions.

Typical MAP Sensor Readings: Key On Engine Off

What to Expect in Normal Conditions?

Under normal conditions, with the key turned on but the engine off, the MAP sensor should read close to atmospheric pressure. This is typically around 4.6 to 4.8 volts, equivalent to 100 kPa or 29.92 inHg at sea level.

Understanding Variations in Readings

Variations in MAP sensor readings can be indicative of several issues. A reading significantly lower or higher than the standard range suggests problems either with the MAP sensor itself or with the engine’s intake manifold.

Diagnosing MAP Sensor Issues

Identifying Common Problems

A faulty MAP sensor can lead to poor engine performance, increased fuel consumption, and higher emissions. Common symptoms include rough idling, stalling, and difficulty in starting the engine.

Steps for Effective Diagnosis

To accurately diagnose MAP sensor issues, one should:

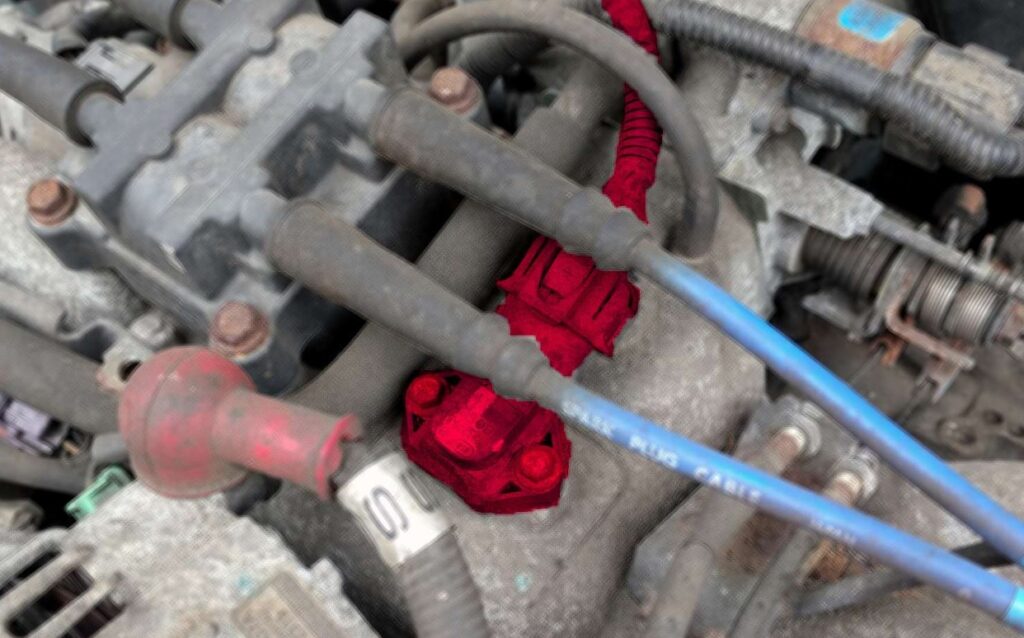

- Check for any visible damage to the sensor.

- Use an OBD-II scanner to read error codes.

- Conduct a voltage test with the key on and the engine off.

Preventive Maintenance and Care

Regular Check-Ups

Regular inspections of the MAP sensor can prevent potential engine issues. Keeping the sensor clean and free from debris is essential for accurate readings.

Importance of Timely Replacements

Replacing a faulty MAP sensor promptly is crucial. Ignoring symptoms can lead to more severe engine problems and costly repairs in the long run.

The Impact of Environmental Factors

Effects of Altitude and Temperature

Environmental factors like altitude and temperature can affect MAP sensor readings. Higher altitudes show lower atmospheric pressure readings, which is normal.

Adapting to Changing Conditions

The ECU adjusts the fuel mixture based on the MAP sensor’s data, adapting to different environmental conditions. This ensures optimal engine performance irrespective of external factors.

What Is A Normal MAP Sensor Reading?

A normal MAP (Manifold Absolute Pressure) sensor reading is crucial for ensuring your vehicle’s engine runs efficiently. Typically, a normal MAP sensor reading with the key on and the engine off should be close to atmospheric pressure.

This is generally around 4.6 to 4.8 volts, corresponding to 100 kPa (kilopascals) or 29.92 inHg (inches of mercury) at sea level. It’s important to note that these values can vary slightly based on altitude and weather conditions.

The MAP sensor’s role in detecting air pressure changes within the intake manifold makes it a key component in the engine’s fuel and air delivery system.

What Should A MAP Sensor Read KPA At Idle?

At idle, the MAP sensor should read a lower value, as the engine’s air demand is minimal. Typically, a MAP sensor will read between 30 to 45 kPa at idle. This lower reading is due to the throttle valve being mostly closed, which reduces the amount of air entering the engine.

The exact value can vary depending on the engine type, altitude, and the state of the engine (such as a cold start vs. a warm-up engine). Consistent readings in this range are a good indicator that the MAP sensor is functioning properly under idle conditions.

How Do I Know If My MAP Sensor Is Bad?

Identifying a bad MAP sensor involves looking for specific symptoms and using diagnostic tools. Common signs of a faulty MAP sensor include poor fuel economy, engine misfires, rough idling, a decrease in engine power, and an illuminated Check Engine light.

Using an OBD-II scanner to read error codes is a definitive way to confirm a MAP sensor issue. Additionally, a fluctuating or incorrect voltage reading from the sensor during testing can also indicate a problem. If the sensor fails to respond or gives erratic readings, it likely needs to be replaced.

Should MAP And BARO Read The Same?

MAP (Manifold Absolute Pressure) and BARO (Barometric Pressure) sensors have different roles but can read similarly under certain conditions. The MAP sensor measures the pressure inside the intake manifold, while the BARO sensor measures the atmospheric pressure.

When the engine is off, but the ignition is on (key on, engine off), the MAP sensor reading should be equal to the BARO sensor reading, as both are measuring atmospheric pressure at that moment.

However, when the engine is running, the MAP reading will vary based on the engine load and throttle position, while the BARO remains constant. Comparing these two readings can also help diagnose issues with the MAP sensor or the engine’s air intake system.

Conclusion

Understanding what a MAP sensor should read key on engine off is essential for maintaining engine health. Regular monitoring and maintenance of the MAP sensor can prevent serious engine problems.

In this context, a standard reading of 4.6 to 4.8 volts is a good indicator of a properly functioning MAP sensor and a healthy engine. Remember, addressing issues promptly can save you from costly repairs and ensure your vehicle runs efficiently.

Top FAQ’s

Can cleaning the MAP sensor improve performance?

Cleaning a MAP sensor can improve performance if the sensor is dirty. Dirt and debris can skew readings. Use appropriate cleaners and be careful not to damage the sensor during cleaning.

How do I test a MAP sensor?

To test a MAP sensor, use a digital multimeter. Check for proper voltage with the key on and engine off, which should be around 4.6 to 4.8 volts. Then, start the engine and check the voltage at idle and during revving. Inconsistent or no change in voltage indicates a faulty sensor.

What should a MAP sensor read at idle?

At idle, a MAP sensor typically reads between 1 and 1.5 volts, corresponding to a lower manifold pressure due to the closed throttle. This reading may vary slightly depending on the vehicle and altitude.

Can a MAP sensor affect transmission shifting?

Yes, a malfunctioning MAP sensor can impact transmission shifting. Modern vehicles use MAP sensor data for transmission control. Incorrect data can cause improper shifting patterns, affecting the vehicle’s overall performance.

Matt Rex brings 12 years of specialized automotive expertise, holding a professional degree in Automotive Engineering Technology. As the founder of Turbochaos, he delivers comprehensive diagnostic services, performance optimization, and fleet maintenance solutions, backed by advanced certifications in hybrid/electric systems and ADAS technology. Its innovative methodologies have earned industry recognition while maintaining a 98% customer satisfaction rate.