Common Problems With DT466 Engine [Explained]

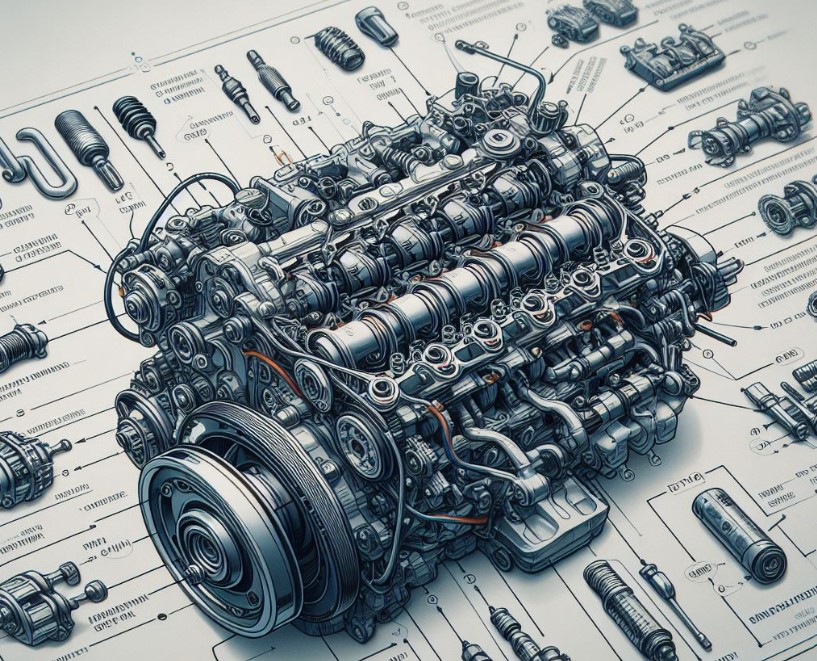

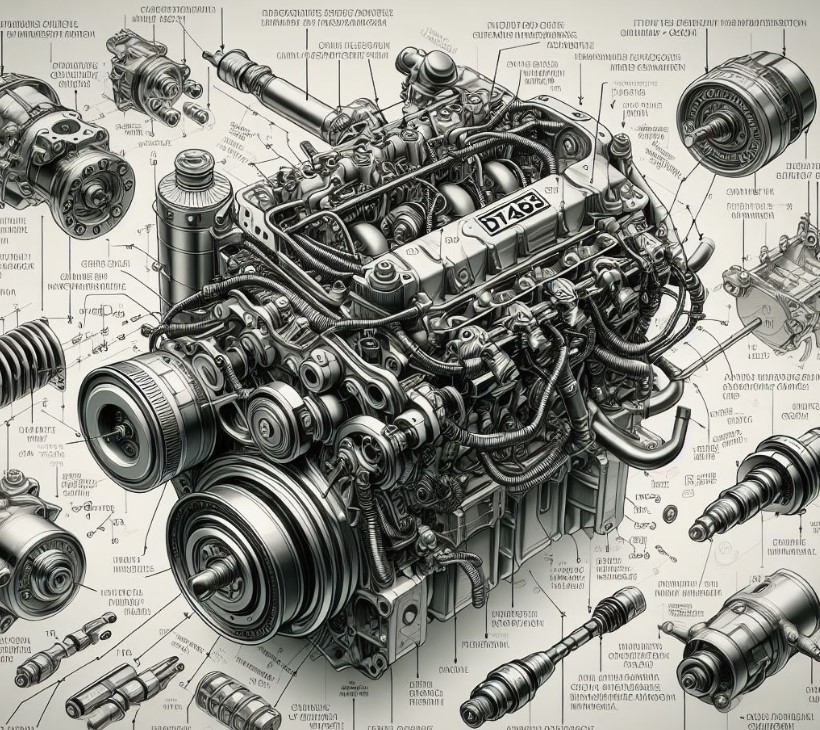

This article will explain Common Problems With DT466 Engine. The DT466 engine is renowned for its durability and performance in heavy-duty vehicles. This powerhouse has been a preferred choice for many in the transportation and industrial sectors. However, like any mechanical system, it’s not immune to issues. Understanding these common problems helps in maintaining optimal functionality and longevity.

Key Takeaways

- Fuel System Issues: Problems with injectors, fuel lines, and filters are common.

- Cooling System Complications: Overheating and radiator issues often occur.

- Oil and Lubrication Challenges: Oil leaks and lubrication failures can happen.

- Turbocharger Troubles: Turbocharger failures can lead to significant power loss.

- Electrical System Concerns: Faulty wiring and sensor malfunctions are typical.

- Emission Control Complications: EGR and DPF issues affect engine performance.

Common Problems With DT466 Engine

One of the most notable problems with the DT466 engine involves the fuel system. Issues here can range from clogged fuel filters to malfunctioning injectors. These problems can severely impact engine performance and efficiency.

Fuel System Issues

Injector Problems

The injectors in the DT466 are critical for its operation. When they malfunction, symptoms like rough idling, power loss, and increased fuel consumption are common. Regular maintenance and timely replacements are crucial to avoid these issues.

Fuel Filter and Line Blockages

Clogged fuel filters and blocked fuel lines can starve the engine of the necessary fuel. This not only diminishes performance but can also cause the engine to shut down unexpectedly.

Cooling System Complications

Overheating

Overheating is a significant concern in the DT466 engine. Causes range from low coolant levels to radiator malfunctions. Regular checks and maintenance of the cooling system are essential to prevent this problem.

Radiator Issues

Radiator problems, such as leaks or blockages, can lead to insufficient cooling. This directly impacts engine temperature and, if left unchecked, can cause severe damage.

Oil and Lubrication Challenges

Oil Leaks

Oil leaks in the DT466 engine can lead to low oil levels, affecting the engine’s lubrication. This can cause increased friction and heat, leading to more severe engine problems.

Lubrication System Failures

Failures in the lubrication system, including the oil pump, can lead to inadequate oil pressure. This scenario is detrimental to the engine’s overall health and performance.

Turbocharger Troubles

The turbocharger is integral to the DT466 engine’s power output. Turbocharger failures can result in a significant loss of power and efficiency, affecting the overall performance of the engine.

Electrical System Concerns

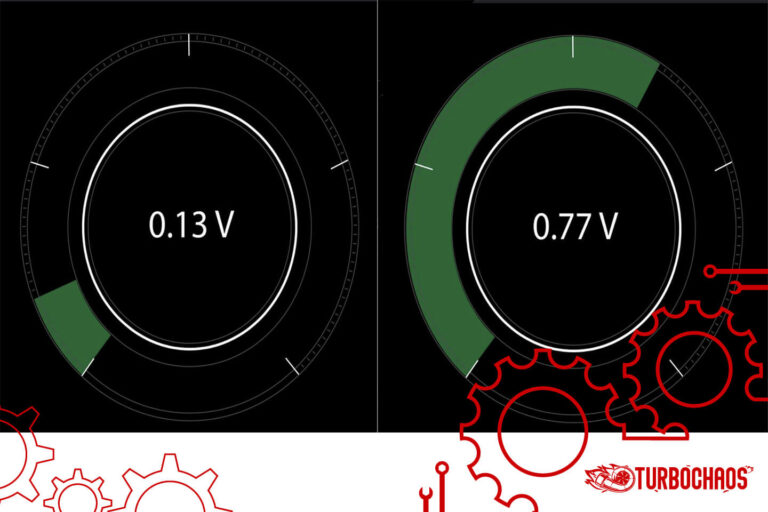

Wiring and Sensor Faults

Electrical issues, particularly with wiring and sensors, can lead to incorrect readings and engine malfunctions. These should be diagnosed and repaired promptly to avoid further complications.

Emission Control Complications

EGR and DPF Problems

Emission control systems like EGR (Exhaust Gas Recirculation) and DPF (Diesel Particulate Filter) are crucial for reducing emissions. Problems with these systems can affect engine performance and lead to failure in emission tests.

What Are the Signs of Fuel System Malfunctions in Heavy-Duty Engines?

Identifying signs of fuel system issues in heavy-duty engines is crucial for timely maintenance. One of the first indicators is a change in the engine’s performance.

This can manifest as reduced power, difficulty starting the engine, or unusual noises during operation. These symptoms often point to problems with fuel injectors or clogged fuel filters. Fuel injectors are responsible for delivering the correct amount of fuel to the engine.

When they malfunction, it results in inefficient fuel consumption and reduced engine power. Similarly, fuel filters play a vital role in keeping contaminants out of the engine. Over time, these filters can become clogged, leading to reduced fuel flow and engine performance.

Another sign to look out for is increased fuel consumption. If the engine starts consuming more fuel than usual, it could indicate a leak in the fuel system or inefficiencies in fuel delivery.

Regular inspections can help identify leaks in fuel lines or tanks, which not only affect performance but also pose safety risks. Maintenance routines should include checking for physical damages, ensuring tight connections, and replacing worn-out components. Timely intervention in these areas can prevent more significant issues and extend the engine’s lifespan.

How Does Overheating Affect Industrial Engines?

Overheating is a critical issue in industrial engines, leading to a host of problems if not addressed promptly. The primary cause of overheating is often a malfunctioning cooling system.

This could be due to low coolant levels, a failing water pump, or a clogged radiator. Low coolant levels can occur from leaks or evaporation over time. Regularly checking and topping up the coolant can prevent this issue.

The water pump, an essential component of the cooling system, circulates coolant throughout the engine. A failing pump can lead to inadequate cooling, causing the engine temperature to rise.

Another aspect to consider is the condition of the radiator. A clogged or leaking radiator cannot effectively dissipate heat, resulting in increased engine temperature.

Debris and sediment can accumulate in the radiator over time, necessitating regular cleaning and maintenance. Overheating can cause significant engine damage, including warped components and decreased oil viscosity, leading to increased friction and wear.

To avoid these problems, operators should ensure the cooling system is in optimal condition, conduct regular inspections, and address any issues immediately. Implementing a robust maintenance schedule can significantly reduce the risk of overheating and prolong the engine’s operational life.

What Are the Challenges in Maintaining Oil and Lubrication in Commercial Vehicles?

Maintaining proper oil and lubrication in commercial vehicles is pivotal for engine health. One of the main challenges in this area is dealing with oil leaks.

Oil leaks can be caused by a variety of factors, including worn seals, gaskets, or damaged oil pans. These leaks not only result in loss of oil but can also lead to contamination of other parts of the vehicle.

Detecting and repairing oil leaks early is essential to prevent more significant engine damage. Regular checks for signs of leaks, such as oil spots under the vehicle or on engine components, are vital.

Another challenge is ensuring the lubrication system functions effectively. This system, which includes the oil pump and filters, must be kept in optimal condition to maintain adequate oil pressure and filtration.

Over time, oil filters can become clogged with debris, reducing their effectiveness and potentially leading to oil contamination. Regularly changing oil and filters according to the manufacturer’s recommendations is crucial.

Additionally, using the right type of oil for the specific engine and operating conditions is important for optimal lubrication and engine performance. Keeping up with these maintenance tasks helps prevent engine wear and extends the vehicle’s lifespan.

How to Diagnose Turbocharger Issues in Transportation Engines?

Diagnosing turbocharger issues in transportation engines is essential for maintaining their efficiency and performance. One of the primary signs of a turbocharger problem is a noticeable decrease in engine power

. This lack of power can be felt during acceleration or when the vehicle struggles to maintain speeds it previously handled with ease. The turbocharger’s role is to boost the engine’s power output by forcing more air into the combustion chamber.

When it fails, this process is hindered, resulting in power loss. Other symptoms include unusual noises from the turbo area, such as whining or sputtering, indicating a potential mechanical issue within the turbocharger.

Another aspect to consider is the presence of excessive smoke from the exhaust. This can be a sign of oil leaking into the combustion chamber, often due to a failing turbocharger seal.

This issue not only affects performance but also poses environmental concerns due to increased emissions. Regular inspections of the turbocharger system, including checking for oil leaks, damaged blades, or blockages in the air pathways, are crucial.

Conducting these checks can help diagnose problems early, preventing more extensive damage to the engine and keeping the vehicle’s performance at its peak.

Conclusion

In conclusion, the DT466 engine is a robust and reliable power unit but not without its share of problems. Addressing common issues like fuel system malfunctions, cooling system complications, oil and lubrication challenges, turbocharger troubles, electrical system concerns, and emission control complications is vital.

Regular maintenance and timely intervention can significantly enhance the engine’s performance and lifespan, ensuring that the DT466 continues to be a dependable choice in the industrial and transportation sectors.

Top FAQ’s

What are common signs of wear in heavy-duty engine components?

Common signs of wear in heavy-duty engine components include oil leaks, unusual noises, decreased performance, and increased fuel consumption. Regular inspections and maintenance are crucial for early detection and repair.

Can a dirty air filter affect engine performance?

Yes, a dirty air filter can significantly affect engine performance by restricting air flow, reducing efficiency, and potentially causing the engine to run richer, leading to higher fuel consumption.

How often should I change the oil in a heavy-duty engine?

The frequency of oil changes in heavy-duty engines depends on usage, but generally, it’s recommended every 10,000 to 15,000 miles. Always refer to the manufacturer’s guidelines for specific intervals.

What should I do if my engine is losing power?

If your engine is losing power, check for common issues like clogged fuel filters, air intake problems, or turbocharger malfunctions. Consulting a professional mechanic for a thorough diagnosis is often necessary.

Matt Rex brings 12 years of specialized automotive expertise, holding a professional degree in Automotive Engineering Technology. As the founder of Turbochaos, he delivers comprehensive diagnostic services, performance optimization, and fleet maintenance solutions, backed by advanced certifications in hybrid/electric systems and ADAS technology. Its innovative methodologies have earned industry recognition while maintaining a 98% customer satisfaction rate.