Are ATK Engines Any Good? A Complete Breakdown

ATK Engines have garnered attention in the automotive world, known for their remanufactured engines that promise both quality and reliability. This leads to the pivotal question: Are ATK Engines Any Good? ATK Engines are considered reliable and offer a good balance of performance and value. They are particularly renowned for their rigorous testing standards and use of high-quality components.

Key Takeaways

- ATK Engines are known for their reliability and quality.

- They undergo stringent testing procedures.

- ATK offers a wide range of engines suitable for various vehicles.

- These engines are a cost-effective alternative to brand-new engines.

- They come with warranties, ensuring customer satisfaction.

Are ATK Engines Any Good?

Yes, ATK engines are good for several reasons:

- Quality and Reliability: They are known for their high-quality construction and reliability.

- Performance: These engines deliver good power for their price, meeting their horsepower claims effectively.

- Ease of Installation: Mechanics find them easy to install and tune.

- Sound and Running: They have a great sound and run well, adding to the driving experience.

- Customer Service: ATK provides excellent customer service, resolving any issues promptly.

ATK engines offer a balance of quality, performance, and reliable customer support, making them a good choice for various automotive needs.

Understanding ATK Engines

Overview of ATK Engine Offerings

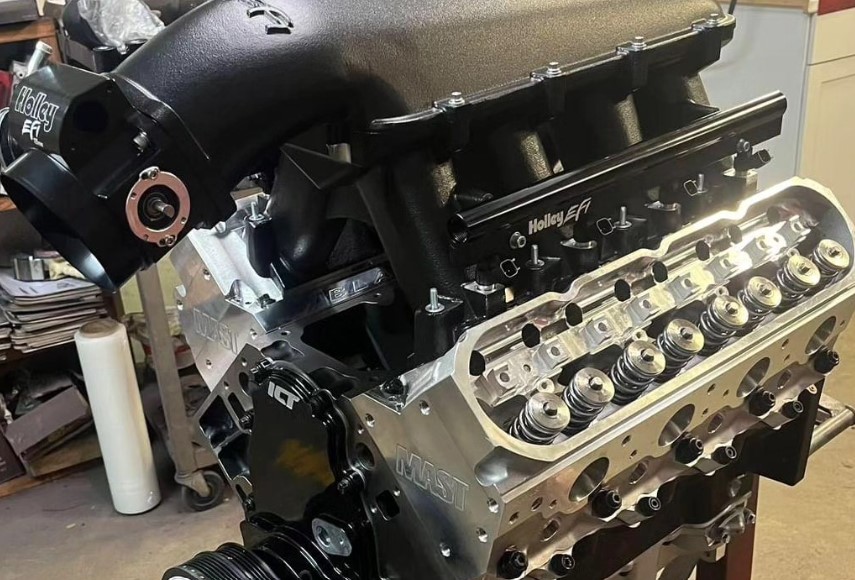

ATK Engines specializes in remanufacturing engines, a process that involves rebuilding an engine with new parts to restore it to its original condition. They offer a wide range of engines, catering to different vehicle models and needs. This includes engines for everyday vehicles, performance cars, and even classic models.

The Remanufacturing Process

The process of remanufacturing an engine at ATK involves several key steps. Each engine is disassembled, cleaned, and inspected for wear and damage. Components that do not meet the original specifications are replaced with new or reconditioned parts. This meticulous process ensures that every ATK engine meets or exceeds OEM specifications.

Quality and Performance

Quality Control and Testing

ATK Engines’ commitment to quality is evident in their testing procedures. Each engine undergoes a series of tests, including pressure testing, vacuum leak detection, and simulated road testing. This comprehensive approach ensures that the engines are reliable and perform as expected.

Customer Feedback and Reviews

Customer reviews and feedback consistently praise ATK Engines for their durability and performance. Users often report a significant improvement in their vehicle’s performance after installing an ATK engine. This customer satisfaction is a testament to the quality and reliability of these engines.

Cost-Effectiveness

Pricing Comparison with New Engines

When compared to purchasing a brand new engine, ATK remanufactured engines are a more cost-effective solution. They offer the performance of a new engine at a fraction of the cost, making them an attractive option for those looking to replace their vehicle’s engine without breaking the bank.

Warranty and After-Sales Support

ATK Engines come with a warranty, providing additional peace of mind to customers. This warranty covers any defects in materials or workmanship, assuring customers of the quality and longevity of their purchase. ATK’s after-sales support is also notable, offering assistance and guidance to customers post-purchase.

Environmental Impact

Sustainable Practices in Engine Remanufacturing

Remanufacturing engines is an environmentally friendly practice. It reduces waste by reusing existing engine components, which in turn decreases the need for new raw materials. ATK’s process aligns with sustainable practices, contributing to a reduction in the environmental impact associated with engine production.

Specific Engine Models and Applications

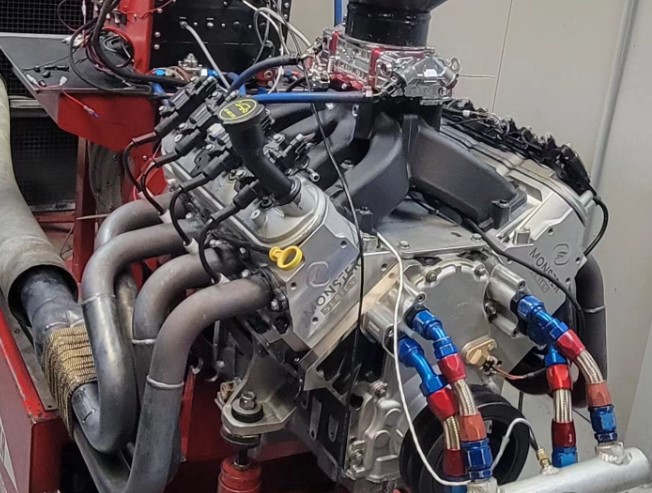

Performance and Specialty Engines

ATK offers a range of performance engines designed for those seeking enhanced power and efficiency. These engines are tailored for specific applications such as racing or heavy-duty usage, demonstrating ATK’s ability to cater to niche markets.

Engines for Classic and Vintage Vehicles

For classic car enthusiasts, finding the right engine can be a challenge. ATK fills this gap by offering engines for vintage vehicles, ensuring these classics run smoothly without compromising their authenticity.

Customer Experiences and Case Studies

Success Stories and Transformations

Various case studies and success stories highlight the transformative impact of installing an ATK engine. Customers report improvements in vehicle performance, fuel efficiency, and overall satisfaction, underscoring the value ATK engines add to their vehicles.

Long-Term Reliability Reports

Long-term reliability is a crucial aspect for any engine. Reports from customers who have used ATK engines for extended periods provide insights into their durability and maintenance requirements, painting a picture of long-term reliability and cost-effectiveness.

Detailed Overview of Remanufacturing Steps

Engine remanufacturing is a meticulous process that revitalizes used engines to meet the original manufacturer’s specifications. This begins with a thorough disassembly and cleaning of the engine. Each part is inspected for wear and damage, with faulty components replaced or repaired.

The process includes machining and refurbishing key components like the cylinder heads, crankshaft, and camshaft. This detailed approach not only extends the life of the engine but also enhances its performance and reliability.

Quality Assurance in Remanufacturing

Quality assurance is paramount in engine remanufacturing. Each step of the process is closely monitored to ensure adherence to strict standards. Precision tools and advanced technology are employed for accurate measurements and diagnostics.

The final product undergoes rigorous testing, including leak, pressure, and performance tests, to ensure it meets or exceeds original specifications. This attention to detail in the remanufacturing process guarantees a high-quality product that is both reliable and efficient.

Engine Longevity and Maintenance

Extending Engine Life through Proper Care

The longevity of a remanufactured engine is significantly influenced by maintenance practices. Regular oil changes, timely replacement of filters, and adherence to service schedules are crucial.

Monitoring engine performance and addressing minor issues promptly can prevent major problems. Proper maintenance not only extends the engine’s lifespan but also ensures optimal performance and fuel efficiency.

Common Maintenance Tips for Engine Health

To maintain engine health, it’s important to be aware of common maintenance tips. This includes regularly checking engine fluids, ensuring the cooling system is functioning properly, and keeping the engine clean to prevent overheating. Regular inspections for leaks or unusual noises can catch issues early. By following these maintenance practices, engine owners can enjoy a smooth and reliable driving experience.

Engine Performance and Efficiency

Enhancing Engine Output

Engine performance is a critical aspect of any vehicle. Remanufactured engines often incorporate modifications and updates that can enhance performance.

Upgrades like improved camshaft profiles, balanced and blueprinted components, and advanced fuel injection systems can lead to increased horsepower and torque, making the engine more responsive and powerful.

Fuel Efficiency in Modern Engines

Fuel efficiency is increasingly important in today’s automotive landscape. Remanufactured engines are often more fuel-efficient than their older counterparts.

This is achieved through precision engineering, fine-tuning, and sometimes incorporating modern technology that improves combustion efficiency. Improved fuel efficiency not only reduces operational costs but also minimizes the environmental impact.

Environmental Impact of Engine Remanufacturing

Sustainability in Automotive Engineering

Engine remanufacturing plays a significant role in sustainable automotive practices. Reusing engine blocks and other components reduces the demand for new raw materials and minimizes waste. This approach aligns with eco-friendly initiatives, reducing the carbon footprint associated with engine production and disposal.

Eco-Friendly Practices in Engine Rebuilding

Eco-friendly practices in engine rebuilding include using recycled materials and minimizing waste during the remanufacturing process. Many remanufacturers also implement energy-efficient methods and technologies to further reduce environmental impact. This commitment to sustainability makes remanufactured engines an attractive option for environmentally conscious consumers.

Warranty and Support for Remanufactured Engines

Understanding Warranty Coverage

Warranty coverage is a critical aspect when purchasing a remanufactured engine. Most remanufacturers offer comprehensive warranties that cover material and workmanship defects. Understanding the terms and duration of the warranty can provide peace of mind and assurance of quality to the buyer.

Post-Purchase Support and Services

After purchasing a remanufactured engine, having access to reliable post-purchase support is essential. Many providers offer technical support, assistance with installation, and advice on maintenance. This level of customer service ensures a positive experience and helps in maximizing the engine’s performance and lifespan.

Conclusion

In conclusion, ATK Engines are a reliable and cost-effective option for those in need of an engine replacement. Their rigorous testing, quality control, and use of high-quality components ensure that their engines stand up to the demands of various driving conditions.

The balance of performance, reliability, and environmental consciousness makes ATK Engines an excellent choice for vehicle owners. ATK engines not only provide a viable alternative to new engines but also contribute to sustainable automotive practices, making them a commendable option in the remanufactured engine market.

Top FAQ’s

What are the common pros and cons of ATK engines according to user reviews?

ATK engines receive positive feedback for their true horsepower ratings, ease of installation and tuning, great sound and performance, and power for the price. However, some issues include limited warranty coverage, challenges with tech and warranty support, problems with the engine’s valve seals, partial labor cost coverage for reinstalling, and significant shipping delays.

What does the ATK engine warranty cover?

ATK’s warranty covers defects in materials and workmanship in the Continental 48 states. The warranty includes long blocks, short blocks, and engines built for forced induction/racing purposes. There are specific terms for different engine stages and limitations, such as exclusion of products used for competition or racing and damage due to installer error or lack of maintenance.

What are ATK’s warranty options?

ATK provides three warranty options: the standard warranty for 3 years with Unlimited Mileage, No Fault Warranty Protection (NFWP) covering one free replacement product and labor at $50 per hour, and No-Fault Warranty Gold (NFWG) including free replacement product, towing and rental allowances, and labor coverage at up to $95 per hour.

What is the recommended break-in procedure for ATK engines?

ATK suggests a detailed break-in procedure, including filling the engine with oil, using mineral-type engine oil with zinc additive, setting the distributor timing, setting ignition timing, properly setting up the carburetor, and specific steps for flat tappet hydraulic cams and roller cam engines. The procedure emphasizes avoiding prolonged idling and includes tips for purging air from the cooling system and ensuring proper seating of piston rings.

Are there any special considerations for installing ATK engines?

During installation, it’s crucial to check all accessories for tightness and potential leaks. The oil system should be primed, especially in engines that haven’t been dyno-tested. The distributor timing and ignition timing need to be set correctly. Additionally, care should be taken to properly set up the carburetor and to avoid trapped air in the cooling system.

Matt Rex brings 12 years of specialized automotive expertise, holding a professional degree in Automotive Engineering Technology. As the founder of Turbochaos, he delivers comprehensive diagnostic services, performance optimization, and fleet maintenance solutions, backed by advanced certifications in hybrid/electric systems and ADAS technology. Its innovative methodologies have earned industry recognition while maintaining a 98% customer satisfaction rate.